Revolutionary Advancements in Modern Agricultural Machinery

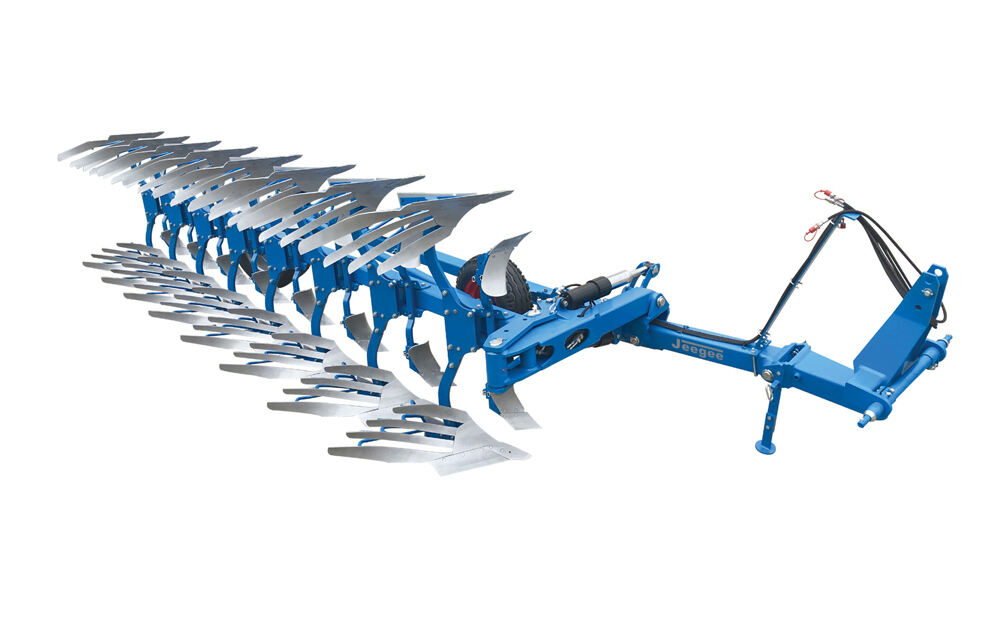

The agricultural landscape has witnessed remarkable transformations over the decades, with the reversible plough standing as a testament to engineering excellence in farming technology. These sophisticated implements have revolutionized soil preparation practices, offering farmers unprecedented efficiency and precision in field operations. Modern reversible plough systems combine robust construction with innovative design features, enabling seamless bidirectional plowing that maximizes productivity while maintaining optimal soil health.

Today's farming operations demand equipment that can handle diverse soil conditions while ensuring consistent performance across vast acreages. The latest reversible plough models incorporate advanced materials and cutting-edge technology to meet these demanding requirements. From small-scale farms to large agricultural enterprises, these implements have become indispensable tools in the modern farmer's arsenal.

Essential Features of Premium Reversible Plough Systems

Advanced Material Construction and Durability

Modern reversible plough manufacturers prioritize durability through the use of high-grade materials. The moldboards are typically constructed from hardened steel with special coatings that resist wear and soil adhesion. These advanced materials ensure longer service life and maintain optimal plowing performance even in challenging soil conditions. The frame structures are engineered using high-tensile steel that provides excellent strength-to-weight ratios, allowing for robust operation without excessive tractor power requirements.

Quality bearings and pivot points incorporate sealed designs that prevent dust and moisture infiltration, significantly reducing maintenance requirements and extending operational life. The implementation of wear-resistant materials in high-stress areas ensures consistent performance throughout multiple seasons of intensive use.

Precision Adjustment Mechanisms

Contemporary reversible plough models feature sophisticated adjustment systems that allow operators to fine-tune their equipment for optimal performance. Working depth control, furrow width adjustment, and blade angle settings can be modified with high precision, ensuring uniform soil turning and consistent furrow formation. Many premium models now incorporate hydraulic adjustment systems that enable operators to make modifications from the tractor cabin, improving efficiency and operator comfort.

The integration of advanced pivoting mechanisms ensures smooth turning sequences while maintaining precise depth control. These systems often feature memory functions that maintain consistent settings across multiple turning operations, ensuring uniform field coverage and soil preparation.

Technology Integration in Modern Ploughing Systems

Smart Control Systems

The evolution of agricultural technology has brought sophisticated control systems to reversible plough operations. Modern implements often feature electronic monitoring systems that provide real-time feedback on working depth, draft force, and operational efficiency. These smart systems help operators optimize their plowing patterns and maintain consistent soil preparation standards across entire fields.

Integration with GPS and precision farming systems allows for automated turning sequences and optimal path planning, reducing operator fatigue and improving overall efficiency. Some advanced models even incorporate telemetry systems that transmit operational data to farm management software, enabling detailed analysis and optimization of plowing operations.

Soil Management Technologies

Advanced reversible plough designs now incorporate sophisticated soil management features. Variable-width systems allow operators to adjust working widths based on soil conditions and tractor power availability. Some models feature integrated soil conditioning elements that help break down clods and level the surface during the plowing operation, reducing the need for secondary tillage operations.

Modern designs also consider soil conservation principles, with features that help maintain proper soil structure and minimize erosion risks. Special moldboard designs ensure optimal soil inversion while preserving beneficial soil aggregates and organic matter distribution.

Economic Benefits and Operational Efficiency

Fuel Efficiency and Power Management

Contemporary reversible plough designs prioritize fuel efficiency through optimized draft requirements and reduced power consumption. Advanced moldboard profiles reduce soil resistance while maintaining effective soil inversion, resulting in lower fuel consumption per hectare. The implementation of high-clearance designs reduces material buildup and maintains consistent operational efficiency throughout extended working periods.

Modern models often feature weight optimization systems that balance the implement for maximum efficiency while minimizing unnecessary strain on the tractor. This thoughtful engineering translates to significant fuel savings over traditional plowing systems.

Maintenance and Longevity Considerations

The latest reversible plough designs incorporate maintenance-friendly features that reduce downtime and operating costs. Quick-change wearing parts and easily accessible adjustment points minimize service time and ensure optimal performance can be maintained with minimal effort. Many manufacturers now offer extended warranty programs, reflecting the confidence in their products' durability and reliability.

Investment in a quality reversible plough typically yields long-term economic benefits through reduced maintenance requirements and extended service life. The implementation of modular designs allows for easy component replacement and upgrades as needed, protecting the farmer's initial investment.

Frequently Asked Questions

What makes modern reversible ploughs more efficient than traditional models?

Modern reversible plough systems incorporate advanced materials, precision adjustment mechanisms, and smart control systems that optimize soil preparation while reducing power consumption. These improvements, combined with ergonomic designs and automated features, significantly increase operational efficiency and reduce operator fatigue.

How do smart control systems enhance ploughing operations?

Smart control systems provide real-time monitoring of working parameters, GPS integration for precise field coverage, and automated turning sequences. These features help maintain consistent plowing depth and patterns while optimizing fuel efficiency and reducing operator workload.

What maintenance practices ensure optimal reversible plough performance?

Regular inspection of wearing parts, proper lubrication of pivot points, and maintaining correct adjustment settings are essential for optimal performance. Modern designs feature quick-change components and easily accessible service points, making maintenance tasks more straightforward and less time-consuming.