Maximizing Agricultural Efficiency Through Proper Implement Care

The reversible plough stands as a cornerstone of modern farming operations, revolutionizing the way agricultural professionals approach soil preparation. This sophisticated implement enables farmers to maintain consistent furrow patterns while working back and forth across their fields, significantly improving efficiency and soil management. Understanding proper maintenance techniques is crucial for ensuring optimal performance and longevity of your reversible plough, ultimately contributing to better crop yields and reduced operational costs.

Agricultural success heavily depends on equipment reliability, and the reversible plough is no exception. Regular maintenance not only extends the life of your implement but also ensures consistent soil turning quality, proper depth control, and efficient fuel consumption. Whether you're managing a small family farm or overseeing large-scale agricultural operations, mastering the essentials of reversible plough maintenance will prove invaluable to your farming success.

Understanding Your Reversible Plough Components

Critical Parts and Their Functions

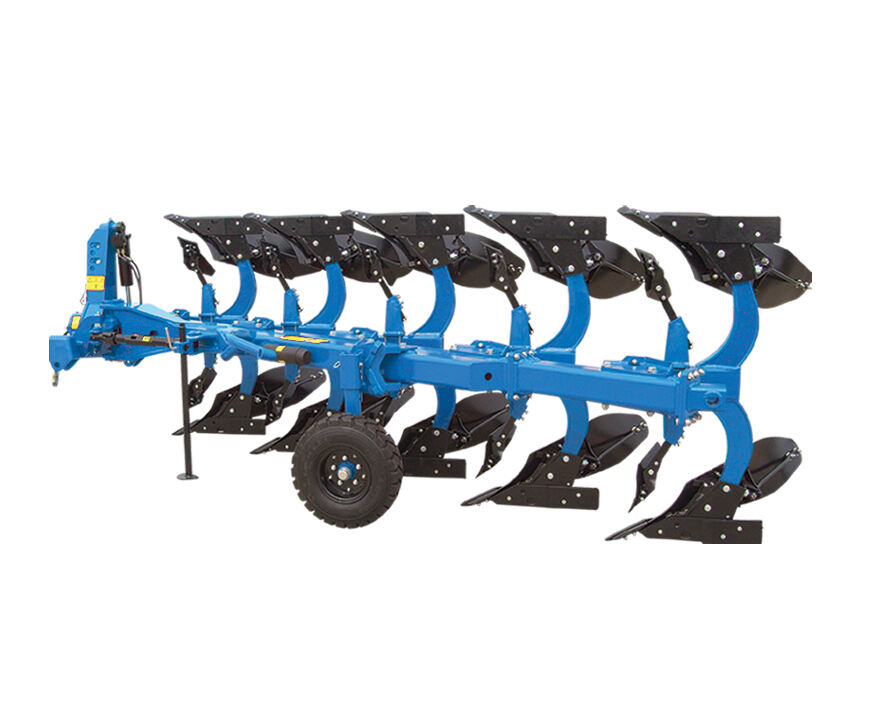

Every reversible plough consists of several key components that work together to deliver optimal soil cultivation. The mouldboard, responsible for lifting and turning the soil, requires particular attention as it experiences the most wear during operation. The share point, which makes the initial soil penetration, works in conjunction with the mouldboard to create clean furrows. The landside provides stability while ploughing, and the headstock enables the crucial reversing mechanism that makes this implement so valuable.

The reversing mechanism itself comprises various moving parts, including hydraulic systems, pivot points, and frame components. Understanding how these elements interact helps farmers identify potential issues before they develop into costly problems. The skimmers, depth wheels, and furrow wideners also play vital roles in achieving precise ploughing results.

Wear Patterns and Common Stress Points

Different parts of the reversible plough experience varying levels of wear depending on soil conditions and usage patterns. The share points and mouldboards typically show the first signs of wear, as they directly engage with abrasive soil particles. Mounting brackets, hydraulic connections, and pivot points may develop stress fatigue over time, especially in challenging soil conditions.

Understanding these wear patterns enables farmers to implement targeted maintenance schedules and anticipate when replacements might be necessary. Regular inspection of these high-stress areas can prevent unexpected breakdowns during critical ploughing periods.

Essential Maintenance Procedures

Daily Inspection Routines

Before each use, operators should conduct thorough visual inspections of their reversible plough. This includes checking all bolts and fasteners for tightness, examining wearing parts for excessive wear or damage, and ensuring all safety mechanisms are functioning correctly. The hydraulic system requires particular attention, including checking for leaks and ensuring proper fluid levels.

Daily maintenance should also include cleaning any soil buildup from the mouldboards and other components. This not only prevents corrosion but also ensures optimal soil flow during operation. Greasing all specified points daily will minimize wear on moving parts and maintain smooth operation.

Seasonal Maintenance Requirements

More comprehensive maintenance procedures should be performed at the beginning and end of each ploughing season. This includes complete disassembly and inspection of wearing parts, thorough cleaning and rust prevention treatments, and careful examination of the frame for any signs of stress or damage. The hydraulic system should undergo a detailed inspection, with oil changes performed according to manufacturer specifications.

Seasonal maintenance is also the ideal time to address any structural repairs, replace worn components, and make adjustments to ensure optimal performance for the upcoming season. Proper documentation of maintenance activities helps track wear patterns and plan future maintenance schedules effectively.

Storage and Protection Practices

Optimal Storage Conditions

Proper storage of your reversible plough significantly impacts its longevity and performance. The implement should be stored in a covered area, protected from direct exposure to weather elements. The storage location should be dry and well-ventilated to prevent moisture accumulation and subsequent rust formation.

Before long-term storage, all metal surfaces should be cleaned and treated with appropriate rust-preventive compounds. The hydraulic system should be properly secured, and all exposed cylinder rods should be fully retracted to prevent corrosion.

Protective Measures During Off-Season

During extended periods of non-use, additional protective measures should be implemented. This includes applying protective coatings to wearing surfaces, ensuring all grease points are fully lubricated, and covering any exposed hydraulic connections. Regular checks during the storage period can identify any developing issues early.

Supporting the reversible plough properly during storage prevents frame distortion and reduces stress on components. Using appropriate stands or blocks ensures weight is distributed evenly and keeps the implement stable throughout the storage period.

Troubleshooting and Repairs

Identifying Common Issues

Experienced operators learn to recognize early warning signs of potential problems with their reversible plough. Unusual sounds during operation, uneven wear patterns, or inconsistent ploughing depth often indicate underlying issues that require attention. Understanding these indicators helps prevent more serious problems from developing.

Regular monitoring of hydraulic system performance, checking for metal fatigue in high-stress areas, and observing soil flow patterns across the mouldboards can reveal potential issues before they affect ploughing quality.

Professional Repair Guidelines

While many maintenance tasks can be performed by operators, some repairs require professional attention. Complex hydraulic system repairs, structural welding, and major component replacements often need specialized equipment and expertise. Establishing a relationship with qualified equipment technicians ensures prompt, reliable service when needed.

Keeping detailed records of repairs, including dates, specific issues addressed, and parts replaced, helps track the implement's maintenance history and aids in planning future maintenance schedules.

Frequently Asked Questions

How often should I replace wearing parts on my reversible plough?

Wearing parts such as shares and mouldboards typically need replacement after 200-400 acres of use, depending on soil conditions and operating practices. Regular inspection can help determine optimal replacement timing based on your specific situation.

What are the signs that hydraulic system maintenance is needed?

Key indicators include slow or uneven turning during reversal, visible oil leaks around seals or connections, and unusual noise during operation. Regular hydraulic oil analysis can also help predict potential system issues before they become serious problems.

How can I prevent rust formation during storage?

To prevent rust, thoroughly clean all components before storage, apply appropriate rust-preventive compounds to metal surfaces, store the implement in a dry, covered area, and perform regular checks during the storage period. Proper drainage of any accumulated moisture is also essential.