Understanding Modern Agricultural Ploughing Technology

The evolution of farming equipment has brought significant advances in ploughing technology, with the reversible plough emerging as a game-changing innovation for modern agriculture. This sophisticated implement has revolutionized soil preparation practices, offering farmers enhanced efficiency and precision in field operations. As we delve into the comparison between reversible plough systems and their traditional counterparts, we'll explore how this technology is reshaping farming practices worldwide.

Agricultural professionals increasingly recognize the reversible plough as a superior option for maintaining soil health and achieving optimal cultivation results. The ability to consistently turn soil in the same direction, regardless of travel direction, represents a fundamental advancement in ploughing technology that addresses many limitations of conventional ploughing methods.

Core Features of Reversible Plough Technology

Advanced Design Elements

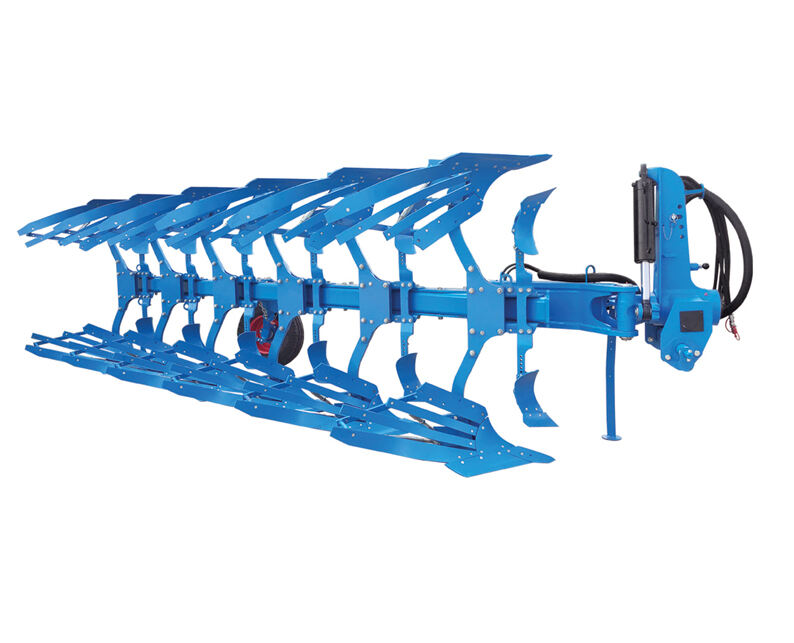

The reversible plough incorporates sophisticated engineering features that set it apart from traditional implements. Its hydraulic system enables smooth rotation of the plough body, allowing operators to maintain straight furrows while working in both directions. The precisely engineered moldboards ensure uniform soil turning and incorporation of crop residues, while adjustable skimmers help manage surface debris effectively.

Modern reversible plough designs also feature advanced wear-resistant materials and replaceable parts, significantly extending the equipment's service life. The implementation of parallel linkage systems ensures consistent ploughing depth and reduced draft requirements, leading to better fuel efficiency and reduced wear on tractor components.

Operational Advantages

When operating a reversible plough, farmers benefit from eliminated dead furrows and enhanced field finish quality. The system allows for continuous ploughing without the need for circular patterns or excessive turning at headlands. This efficiency translates into significant time savings and reduced fuel consumption during field operations.

The ability to maintain consistent ploughing depths and create uniform furrows contributes to improved seedbed preparation and better crop establishment. Additionally, the reversible plough's design minimizes soil compaction by eliminating the need for repeated passes over the same ground.

Economic Benefits and Production Efficiency

Cost-Effectiveness Analysis

While the initial investment in a reversible plough may be higher than traditional implements, the long-term economic benefits often justify the expense. Reduced operating hours, lower fuel consumption, and decreased maintenance requirements contribute to significant cost savings over time. Farmers report enhanced productivity through faster field completion and reduced downtime for adjustments and repairs.

The improved soil management capabilities of reversible plough systems also contribute to better crop yields and reduced input costs. The uniform incorporation of crop residues and consistent seedbed preparation lead to more efficient use of fertilizers and better weed control, further enhancing the economic benefits.

Productivity Improvements

Field efficiency metrics consistently show that reversible plough operations can cover more ground in less time compared to conventional ploughing methods. The elimination of unnecessary turning and overlapping passes results in optimal land utilization and reduced operator fatigue. These improvements in operational efficiency translate directly to increased farm productivity and better resource management.

Modern reversible plough systems also integrate well with precision farming technologies, allowing for variable depth control and automatic adjustment based on soil conditions. This integration enhances overall farm management capabilities and supports data-driven decision-making processes.

Environmental Impact and Sustainability

Soil Conservation Benefits

The reversible plough demonstrates superior capabilities in soil conservation compared to traditional ploughing methods. Its design promotes better moisture retention and reduces erosion risks by maintaining consistent soil structure across fields. The uniform incorporation of crop residues helps build organic matter content and supports beneficial soil microorganism populations.

Research indicates that fields worked with reversible plough systems show improved water infiltration rates and reduced surface runoff. These characteristics contribute to better drought resistance and more sustainable long-term soil management practices.

Carbon Footprint Reduction

The increased efficiency of reversible plough operations leads to significant reductions in fuel consumption and corresponding greenhouse gas emissions. The reduced number of passes required for field preparation, combined with more efficient power utilization, supports farm operations' environmental sustainability goals.

Additionally, the improved soil management capabilities of reversible plough systems contribute to enhanced carbon sequestration in agricultural soils. This aspect becomes increasingly important as farms work to reduce their environmental impact and meet sustainability targets.

Maintenance and Long-term Care

Regular Maintenance Procedures

Proper maintenance of a reversible plough ensures optimal performance and longevity. Regular inspection and replacement of wear parts, such as shares and moldboards, help maintain consistent ploughing quality. Hydraulic system maintenance, including regular fluid checks and seal replacement, prevents operational issues and extends equipment life.

Implementing a structured maintenance schedule, including proper storage and protection from weather elements, significantly reduces repair costs and equipment downtime. Training operators in proper adjustment and operation techniques further contributes to equipment longevity.

Performance Optimization

Achieving optimal performance from a reversible plough requires regular adjustments based on soil conditions and operating requirements. Proper setup of working depth, furrow width, and draft angle ensures efficient operation and consistent results. Regular monitoring and adjustment of wear patterns help maintain optimal cutting angles and reduce power requirements.

Advanced users often implement precision farming data to optimize plough settings for different field conditions, maximizing efficiency and reducing operating costs while maintaining high-quality results.

Frequently Asked Questions

What makes a reversible plough more efficient than traditional ploughs?

A reversible plough offers superior efficiency through its ability to plough in both directions, eliminating the need for circular patterns and reducing turning time at headlands. This design results in better field finish, reduced fuel consumption, and improved time management in field operations.

How does the initial cost of a reversible plough compare to traditional implements?

While reversible plough systems typically require a higher initial investment, the increased productivity, reduced operating costs, and improved soil management capabilities often result in a favorable return on investment within a few seasons of operation.

What are the main maintenance requirements for a reversible plough?

Regular maintenance includes inspecting and replacing wear parts, maintaining the hydraulic system, checking and adjusting working angles, and ensuring proper lubrication of all moving components. Proper storage and protection from weather elements are also essential for long-term reliability.

How does a reversible plough contribute to sustainable farming practices?

Reversible plough systems support sustainable farming through reduced fuel consumption, improved soil conservation, better residue management, and enhanced water retention capabilities. These benefits contribute to long-term soil health and reduced environmental impact of farming operations.