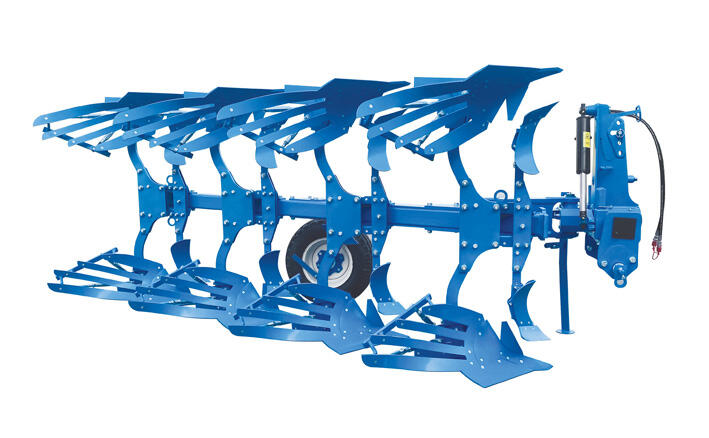

reversible plough for sale

The reversible plough represents a significant advancement in agricultural technology, offering farmers and agricultural professionals a versatile and efficient soil cultivation solution. This implement features a unique design that allows for continuous ploughing in the same direction, eliminating the need for circular ploughing patterns. The construction typically includes multiple moldboards mounted on a robust frame, with hydraulic systems enabling smooth rotation of the plough body. Each moldboard is precisely engineered to ensure optimal soil turning and incorporation of crop residues. The plough's working width can be adjusted to accommodate different field conditions and tractor power ratings, typically ranging from 2 to 8 furrows. Advanced models feature automatic stone release mechanisms, protecting the equipment from damage in rocky conditions. The depth control system ensures consistent ploughing depth, while the furrow width adjustment mechanism allows for precise control over soil manipulation. These ploughs are compatible with modern GPS and precision farming systems, enabling exact furrow alignment and optimal field coverage. The implement's design also incorporates wear-resistant materials in high-stress areas, ensuring longevity and maintaining performance over extended periods of use.