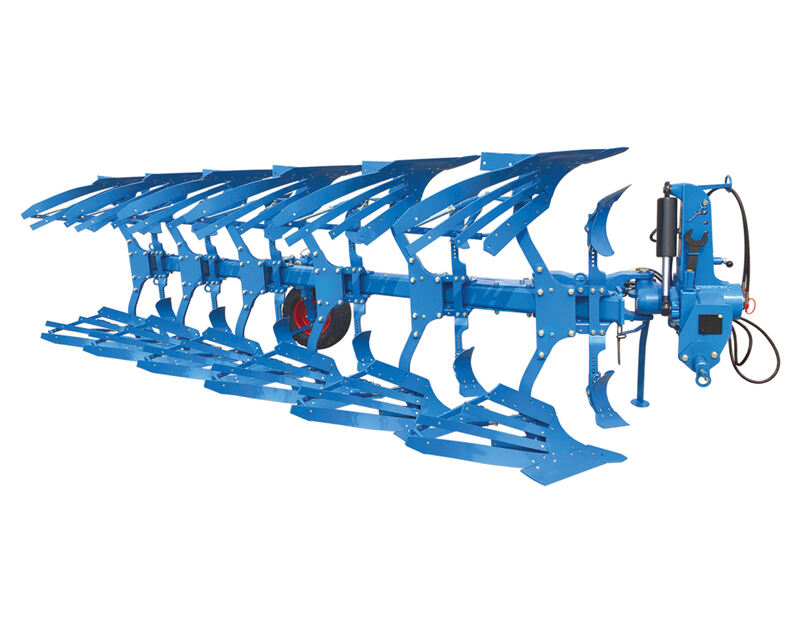

popular reversible plough

The reversible plough represents a significant advancement in agricultural machinery, designed to enhance farming efficiency and soil management. This versatile implement features a unique mechanism that allows farmers to turn the plough body at the end of each furrow, enabling continuous ploughing in the same direction across the field. The design typically incorporates multiple moldboards mounted on a robust frame, with a sophisticated hydraulic system that controls the rotation mechanism. Each plough body is equipped with replaceable shares and moldboards, ensuring optimal soil inversion and consistent furrow formation. The working width can be adjusted to accommodate different soil conditions and tractor power capabilities, typically ranging from 12 to 20 inches per furrow. Modern reversible ploughs often include safety mechanisms such as auto-reset systems that protect the implement from damage when encountering obstacles. The plough's depth control system maintains consistent working depth, while the furrow width adjustment ensures uniform soil turning. These technical features combine to create an implement that not only improves field efficiency but also contributes to better soil structure and crop yield potential.