hydraulic reversible plough price

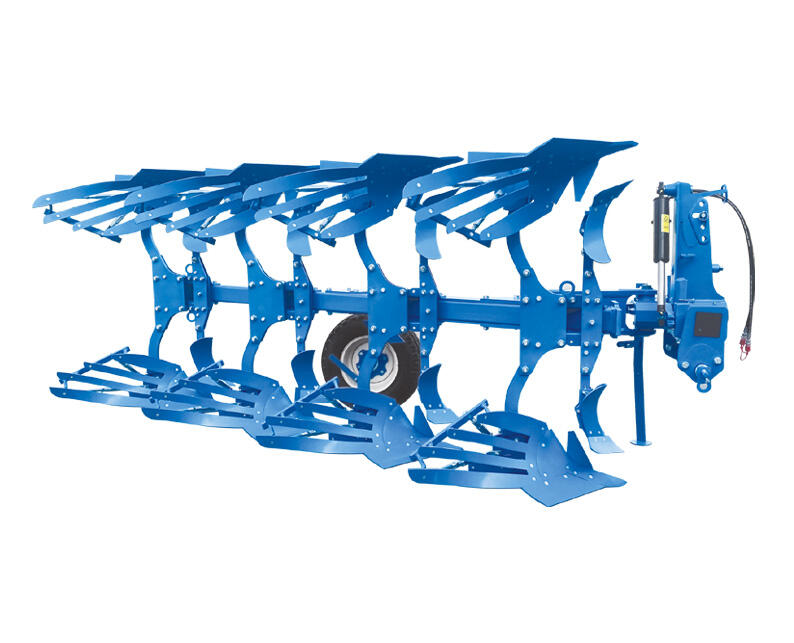

The hydraulic reversible plough price represents a significant investment consideration in modern agriculture, offering farmers a versatile and efficient soil cultivation solution. These implements typically range from $5,000 to $25,000, depending on size, features, and manufacturer reputation. The pricing structure reflects the sophisticated engineering that allows for seamless field operation, with hydraulic systems enabling smooth plough reversal at headlands. Multiple furrow configurations, ranging from 2 to 8 bodies, impact the final cost, while additional features such as auto-reset protection systems, depth control mechanisms, and adjustable furrow width settings contribute to price variations. The investment considers the implement's capacity to operate in various soil conditions, its durability under continuous use, and the inclusion of wear-resistant materials in critical components. Modern hydraulic reversible ploughs incorporate advanced technical features like precision depth adjustment, optimized cutting angles, and efficient furrow formation systems, all of which influence the price point. Manufacturers often offer different specification levels, from entry-level models for smaller farms to premium versions with comprehensive features for large-scale operations.