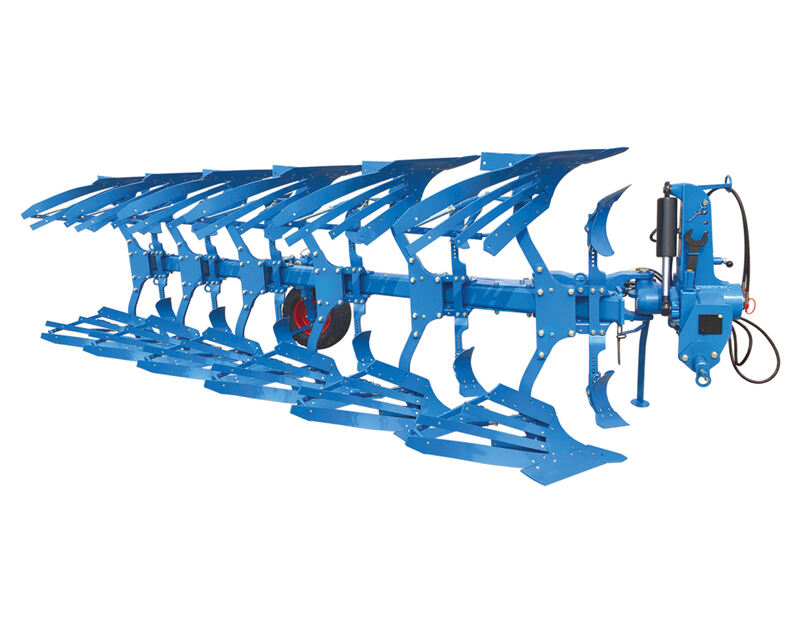

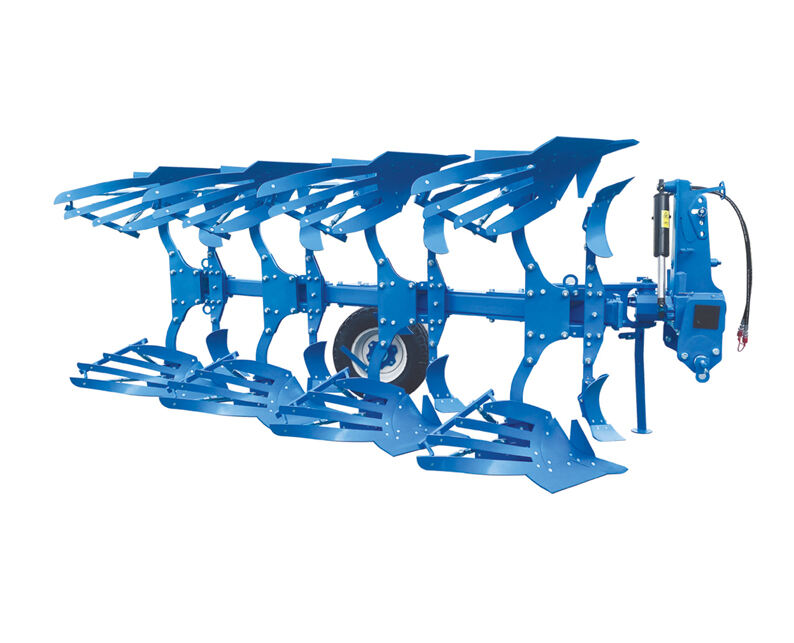

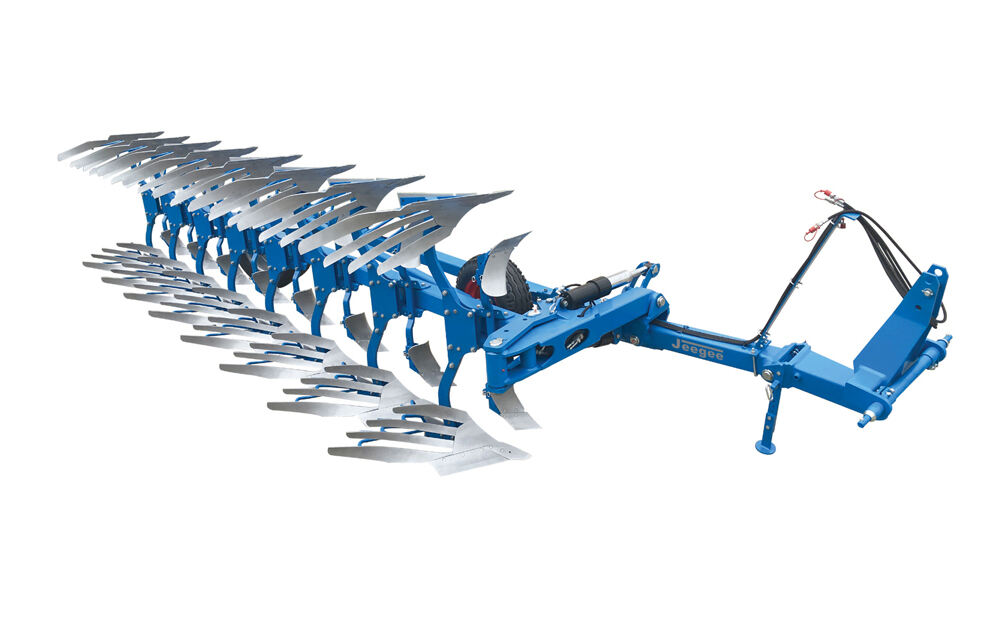

different types of plough

Ploughs are essential agricultural implements that have evolved significantly over time, encompassing various types designed for different farming needs. The primary types include moldboard ploughs, disc ploughs, chisel ploughs, and reversible ploughs. Moldboard ploughs feature a curved blade that effectively turns over soil, burying crop residues and weeds while bringing nutrient-rich subsoil to the surface. Disc ploughs utilize concave metal discs mounted at angles to cut and turn soil, particularly effective in harder or rocky ground conditions. Chisel ploughs are designed with strong tines that break up soil compaction without inverting it, preserving soil structure and moisture. Reversible ploughs offer the advantage of bidirectional ploughing, increasing efficiency by eliminating the need for circular ploughing patterns. Modern ploughs often incorporate technological features such as hydraulic systems for depth control, automatic stone protection mechanisms, and GPS guidance systems for precise operation. These implements are crucial in preparing seedbeds, managing crop residues, and maintaining soil health across various agricultural applications.