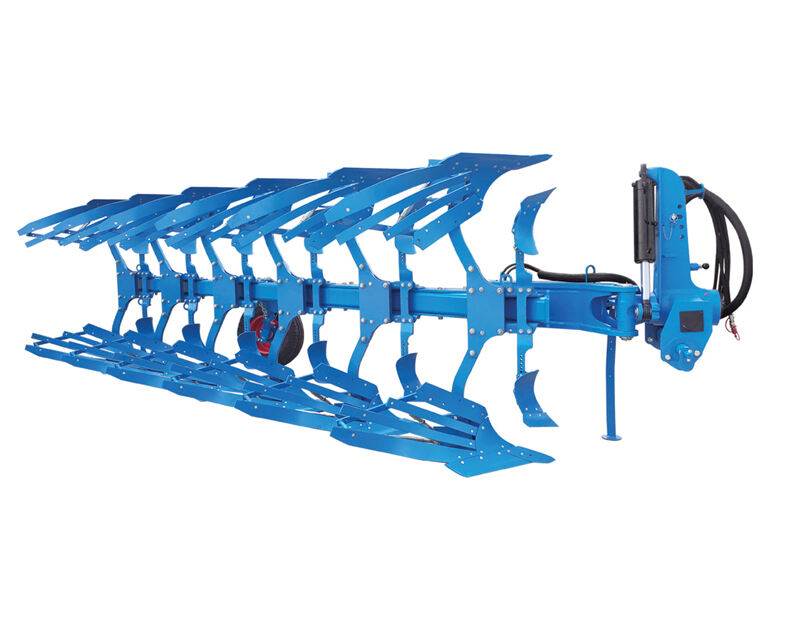

disc plough types

Disc ploughs represent essential agricultural implements designed for primary tillage operations. These implements consist of multiple concave discs mounted at specific angles to effectively cut, lift, and turn over soil. There are several types of disc ploughs, including single-direction disc ploughs, reversible disc ploughs, and offset disc ploughs, each serving specific agricultural needs. Single-direction disc ploughs are ideal for regular field operations, featuring a straightforward design with discs arranged in a single line. Reversible disc ploughs offer enhanced versatility with the ability to turn soil in both directions, making them particularly useful for contour ploughing and working on hillsides. Offset disc ploughs are designed with discs positioned at an angle to the direction of travel, allowing for effective soil mixing and residue incorporation. Modern disc ploughs incorporate advanced features such as hydraulic depth control systems, adjustable disc angles, and protective mechanisms against obstacles. These implements are particularly effective in handling tough soil conditions, heavy crop residue, and virgin land. The technological advancement in disc plough design has led to improved durability, reduced maintenance requirements, and enhanced operational efficiency across various soil types and farming conditions.