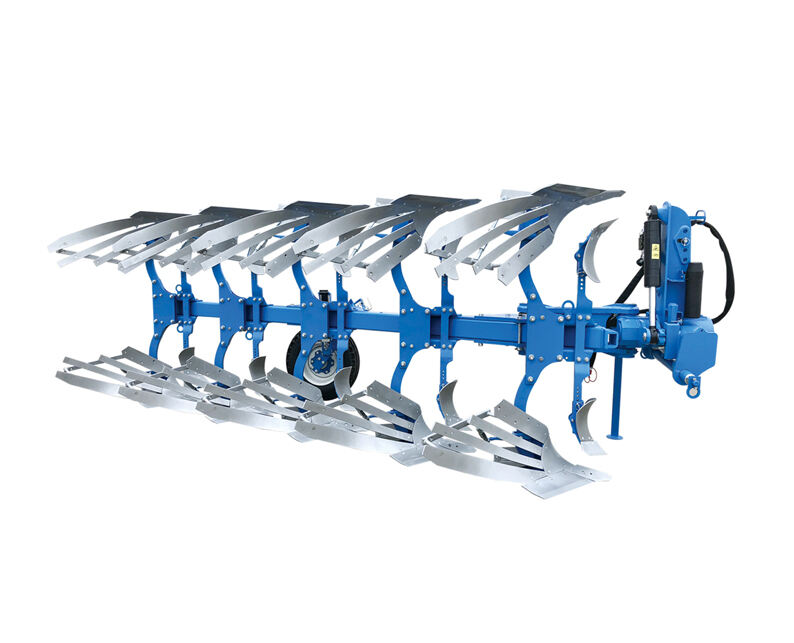

6 disc harrow

The 6 disc harrow represents a versatile and efficient agricultural implement designed to optimize soil preparation and field management. This robust piece of equipment features six precisely engineered discs mounted on a sturdy frame, allowing for effective soil breaking, mixing, and leveling operations. Each disc is carefully positioned to ensure optimal cutting angles and soil penetration, enabling thorough ground preparation for various agricultural applications. The implement's design incorporates adjustable disc angles and working depths, providing farmers with the flexibility to adapt to different soil conditions and cultivation requirements. The 6 disc harrow excels in breaking down crop residue, incorporating organic matter into the soil, and creating an ideal seedbed for planting. Its compact yet powerful configuration makes it suitable for both small-scale farming operations and medium-sized agricultural plots. The harrow's construction emphasizes durability with high-grade steel components and sealed bearings that ensure consistent performance and minimal maintenance requirements. Modern iterations often include features such as hydraulic adjustment systems and protective elements to prevent damage from field obstacles, enhancing both usability and longevity.