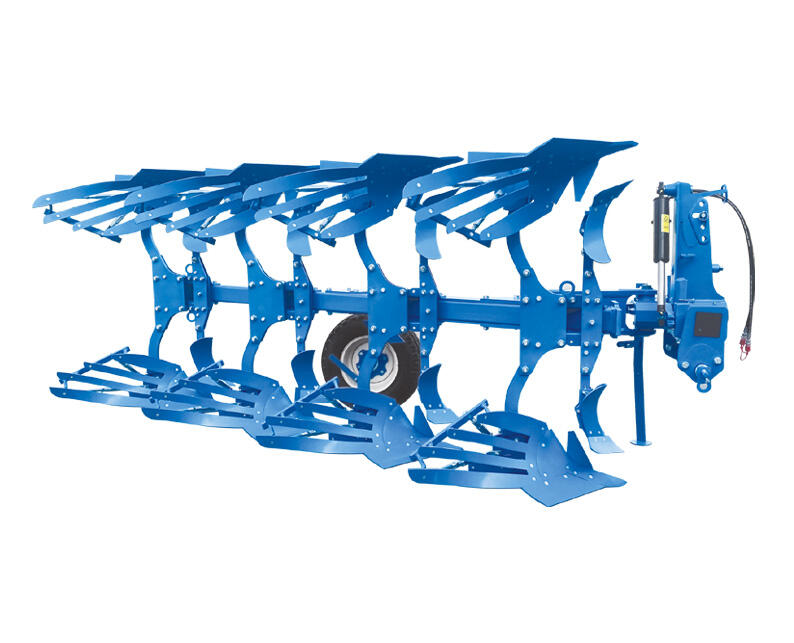

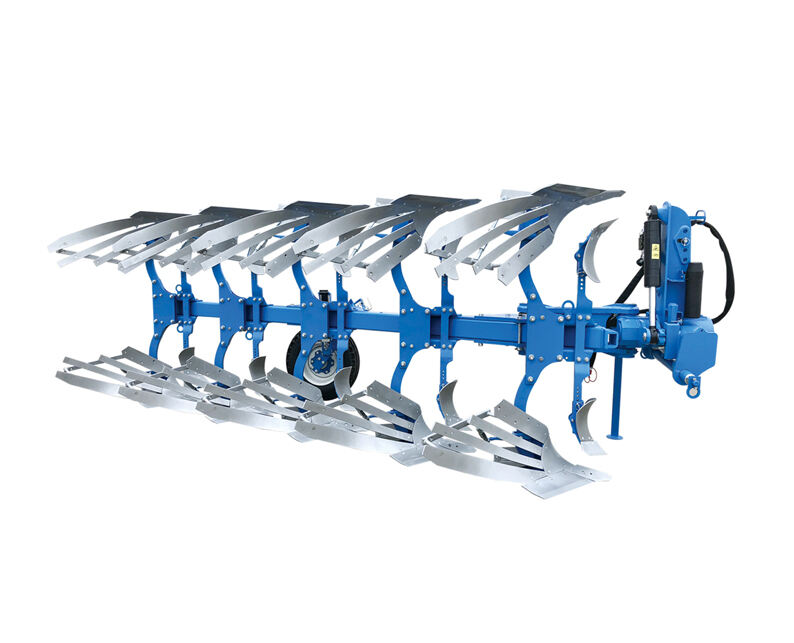

6 ft disc harrow

The 6 ft disc harrow represents a versatile and efficient agricultural implement designed to optimize soil preparation and field management. This robust piece of equipment features precisely engineered discs mounted on a sturdy frame, spanning a working width of 6 feet, making it ideal for small to medium-sized farming operations. The implement excels in breaking up soil clumps, incorporating crop residue, and creating an optimal seedbed for planting. Each disc is carefully positioned to ensure maximum soil penetration and consistent tillage depth, while the spacing between discs promotes efficient soil movement and residue flow. The harrow's design allows for adjustable disc angles, enabling farmers to adapt to various soil conditions and tillage requirements. Built with heavy-duty bearings and axles, the 6 ft disc harrow ensures durability and reliable performance even in challenging field conditions. The equipment's manageable size makes it particularly suitable for operations using compact or utility tractors, offering excellent maneuverability while maintaining productive coverage rates.