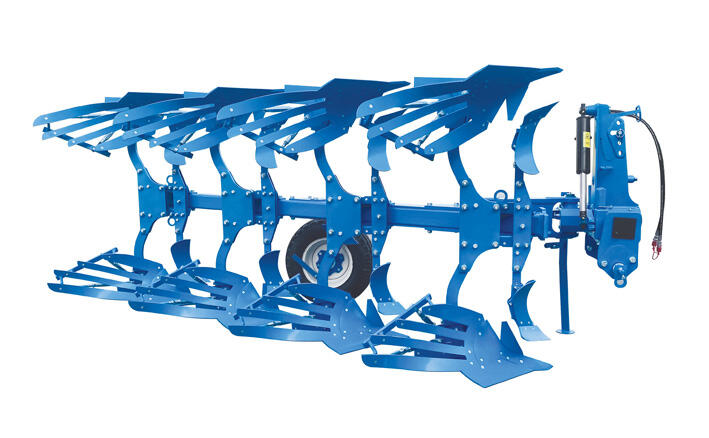

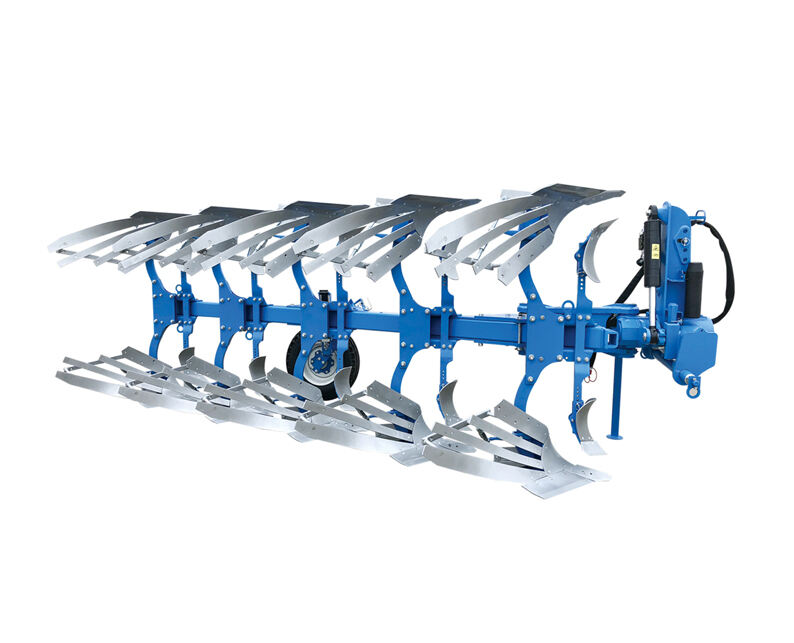

3 bottom plough

The 3 bottom plough represents a significant advancement in agricultural machinery, designed to efficiently turn and aerate soil while preparing it for cultivation. This implement typically consists of three moldboards mounted on a robust frame, capable of simultaneously cutting and inverting three furrow slices of soil. Each bottom includes essential components such as the share, moldboard, landside, and shin, working in harmony to achieve optimal soil preparation. The plough operates at depths ranging from 6 to 12 inches, depending on soil conditions and farming requirements. Modern 3 bottom ploughs often feature adjustable working widths, typically ranging from 14 to 16 inches per bottom, allowing farmers to optimize their field operations. The implement's design incorporates safety features and mechanical advantages that reduce the power requirement while maintaining excellent soil inversion quality. Advanced models include spring-loaded auto-reset mechanisms to protect against damage from hidden obstacles, and precise depth control systems to ensure consistent ploughing depth. The 3 bottom plough is particularly well-suited for medium to large-scale farming operations, offering an ideal balance between operational efficiency and power requirements. Its versatility makes it effective in various soil conditions, from light sandy soils to heavier clay compositions, making it a valuable tool for diverse agricultural applications.