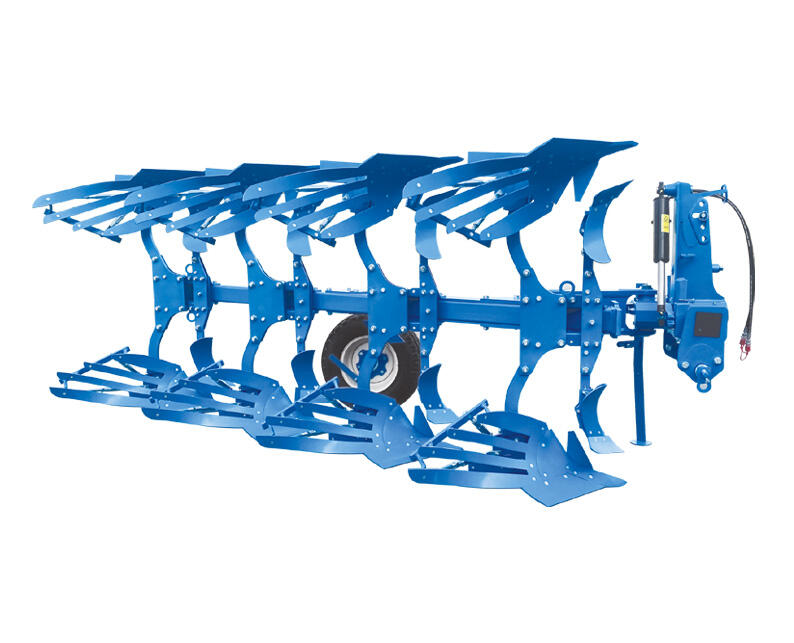

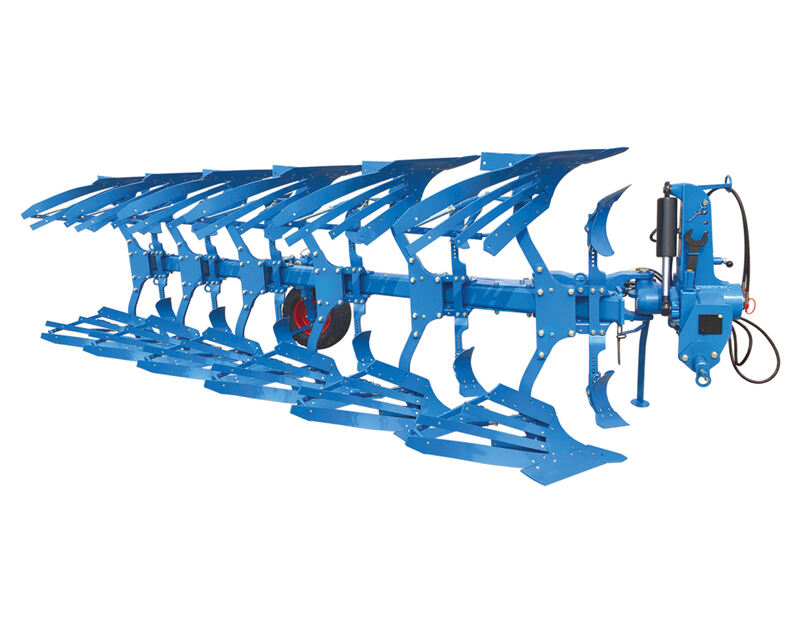

tractor disc plough

A tractor disc plough represents a crucial advancement in modern agricultural machinery, designed to efficiently break and turn soil in preparation for planting. This implement consists of multiple concave steel discs mounted at specific angles on a robust frame, enabling effective soil penetration and turnover. The discs, typically ranging from 24 to 36 inches in diameter, rotate while moving through the soil, cutting through crop residue and weeds while simultaneously lifting and inverting the soil layers. This action helps incorporate organic matter, improve soil structure, and create optimal conditions for seed placement. The tractor disc plough's versatility allows it to perform effectively in various soil conditions, from light sandy soils to heavy clay, making it an invaluable tool for both small-scale farmers and large agricultural operations. Modern disc ploughs often feature adjustable disc angles and working depths, enabling farmers to customize their tillage operations based on specific field conditions and crop requirements. The implement's design also includes safety features such as spring-loaded disc assemblies that protect against damage from hidden obstacles, ensuring long-term reliability and reduced maintenance costs.