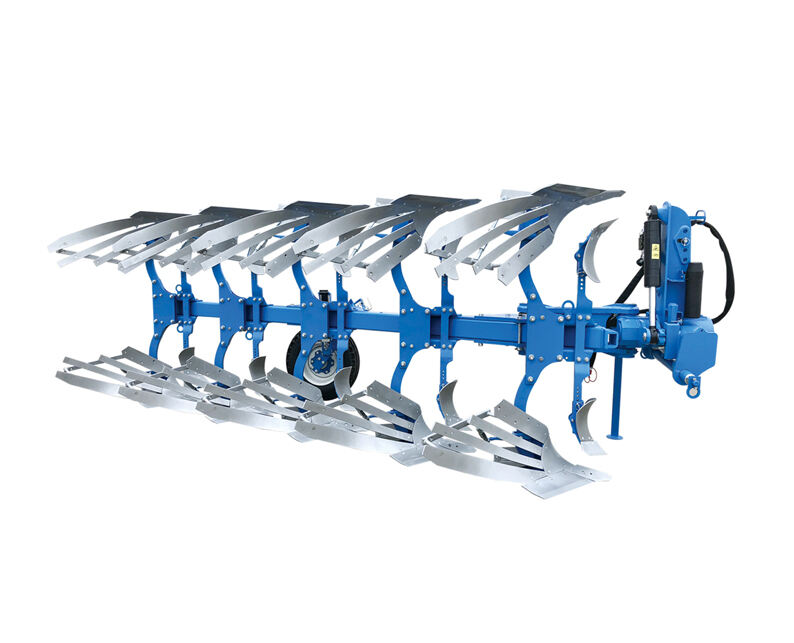

heavy duty disk harrow

The heavy duty disk harrow represents a crucial advancement in agricultural machinery, engineered specifically for intensive soil preparation and management. This robust implement features multiple rows of concave steel disks mounted on a sturdy frame, designed to effectively cut through and mix soil, crop residue, and vegetation. Operating at depths of up to 15 inches, these machines excel in breaking down compacted soil layers and incorporating organic matter. The disks, typically ranging from 24 to 36 inches in diameter, are precisely angled to optimize soil penetration and turning action. Advanced models include hydraulic adjustment systems that allow operators to modify disk angle and depth settings from the tractor cabin, ensuring optimal performance across varying soil conditions. The implement's heavy weight, often exceeding 1000 pounds per foot of working width, provides the necessary downforce for consistent soil engagement. Modern heavy duty disk harrows also incorporate maintenance free bearings, specialized disk scrapers to prevent soil buildup, and transport systems that enable safe movement between fields. This equipment proves invaluable in both primary and secondary tillage operations, offering versatility in managing different soil types and field conditions.