disc plough use

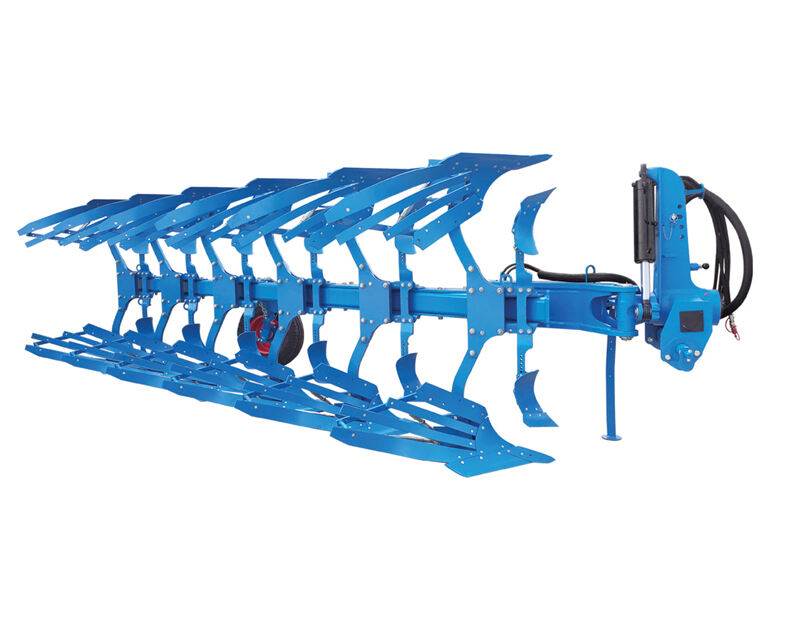

A disc plough represents a fundamental advancement in agricultural machinery, designed to efficiently turn and break up soil while incorporating crop residue. This implement consists of large, concave metal discs mounted at specific angles on a robust frame, typically ranging from 20 to 36 inches in diameter. When pulled by a tractor, these discs rotate and cut into the soil, effectively lifting and turning it over to create a well-aerated seedbed. The unique design allows for superior performance in various soil conditions, particularly in areas with heavy clay or where conventional moldboard ploughs might struggle. Each disc operates independently, enabling the plough to navigate around obstacles while maintaining consistent working depth. The implement's versatility extends to both primary and secondary tillage operations, making it particularly valuable in conservation agriculture practices. Modern disc ploughs often feature adjustable disc angles and spacing, allowing farmers to optimize performance based on specific soil conditions and crop requirements. The technology incorporated in current models includes precision depth control systems, specialized bearing assemblies for extended service life, and enhanced safety features. These implements prove especially effective in handling heavy crop residue, making them invaluable in no-till farming systems and stubble management applications.