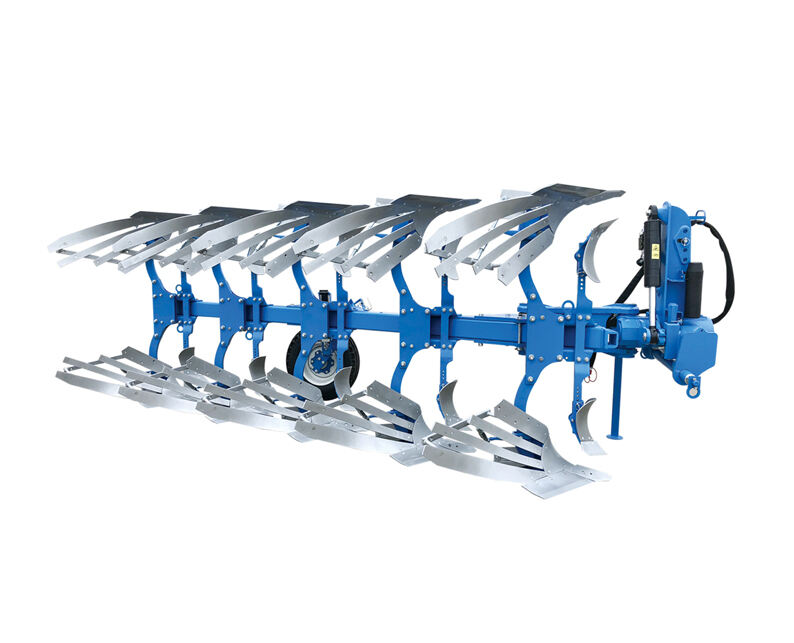

disc plough and disc harrow

The disc plough and disc harrow are essential agricultural implements designed for efficient soil preparation and cultivation. The disc plough features a series of concave metal discs mounted at specific angles, cutting and turning soil while effectively burying crop residue and weeds. Operating at depths between 6 to 12 inches, it excels in breaking through hard soil conditions and managing heavy crop residue. The disc harrow, complementing the plough, consists of multiple rows of steel discs arranged in gangs, working to break down soil clumps, level the field, and create an optimal seedbed. Modern designs incorporate hydraulic systems for precise depth control and adjustable disc angles, allowing farmers to adapt to various soil conditions. These implements prove particularly valuable in heavy clay soils, rocky terrain, and areas with substantial crop residue. They facilitate proper soil aeration, water penetration, and nutrient distribution, while their robust construction ensures durability in challenging field conditions. Advanced models now feature maintenance-free bearings, specialized disc materials for extended wear life, and modular designs for easy parts replacement.