disc harrow 3 point

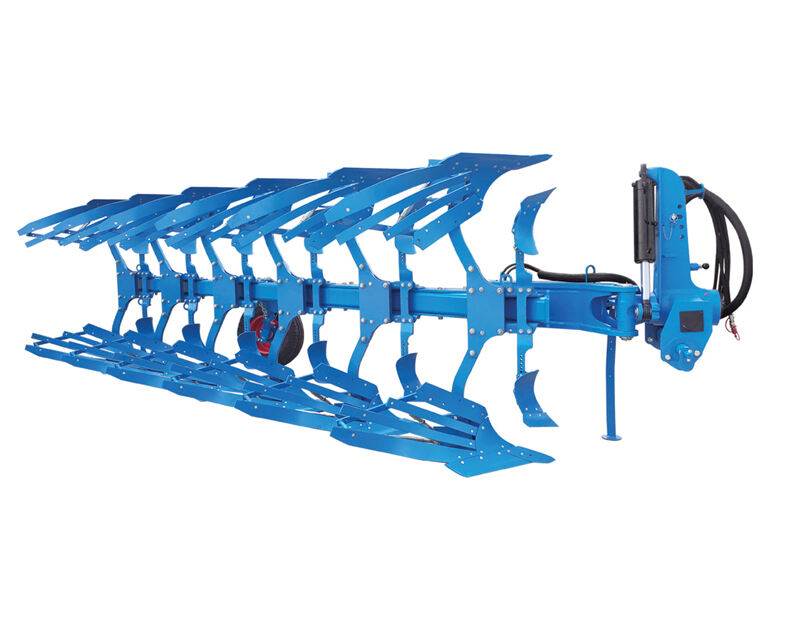

The disc harrow 3 point is a versatile agricultural implement designed to optimize soil preparation and field management. This robust equipment attaches to a tractor's three point hitch system, providing excellent stability and maneuverability during operation. The implement features two sets of concave discs arranged in opposing angles, which effectively cut, turn, and mix soil while breaking down crop residue. The three point mounting system ensures precise depth control and uniform soil cultivation across various terrain conditions. Modern disc harrows typically incorporate adjustable disc angles, allowing farmers to customize the intensity of soil manipulation based on specific field requirements. The implement's design enables efficient coverage of large areas while maintaining consistent working depth, making it ideal for both primary and secondary tillage operations. Advanced models often include hydraulic adjustment systems for disc angle and depth control, enhancing operational efficiency and reducing operator fatigue. The disc harrow 3 point's robust construction, typically featuring heat-treated steel discs and heavy duty bearings, ensures long term durability and reliable performance in demanding agricultural conditions.