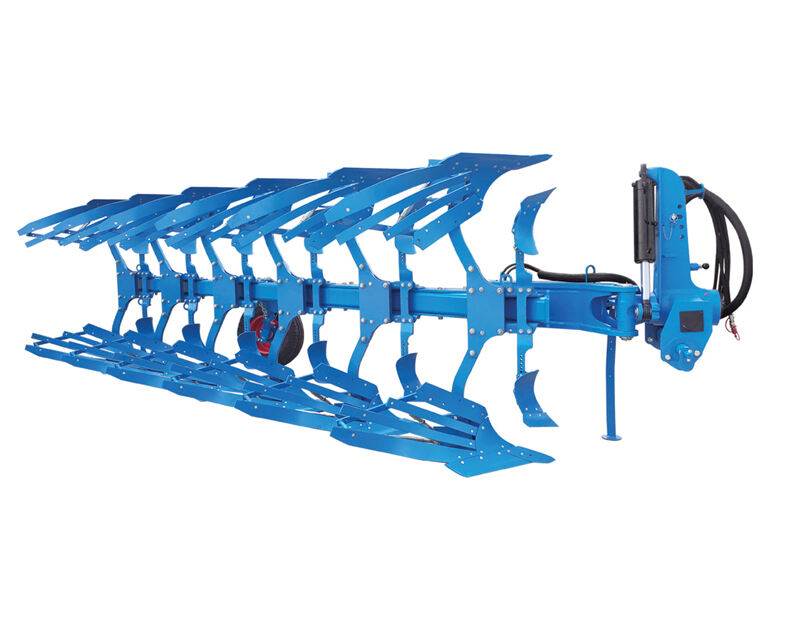

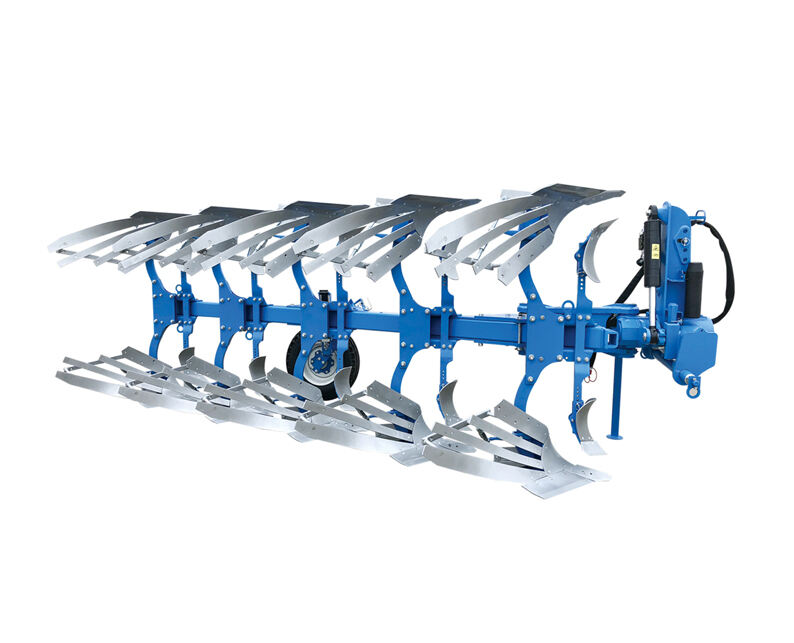

best disc harrow

The best disc harrow represents the pinnacle of modern agricultural technology, combining robust construction with precision engineering to deliver superior field preparation. This essential farming implement features precisely engineered concave discs arranged in multiple rows, typically crafted from high-grade steel for maximum durability and performance. The discs work in harmony to slice through soil, crop residue, and stubble while simultaneously turning and mixing the soil to create an optimal seedbed. Advanced features include hydraulic depth control systems that allow operators to adjust working depth on the fly, ensuring consistent soil preparation across varying field conditions. The harrow's sophisticated bearing systems are sealed and maintenance-free, significantly reducing downtime and operating costs. With working widths available from 8 to 40 feet, these implements can be matched to tractors of various sizes, making them suitable for both small-scale and large commercial operations. The best disc harrows also incorporate innovative weight distribution systems that maintain consistent ground pressure across the entire working width, resulting in uniform soil preparation. These machines excel in various applications, from primary tillage in heavy residue conditions to secondary tillage for seedbed preparation, demonstrating remarkable versatility in different soil types and agricultural scenarios.