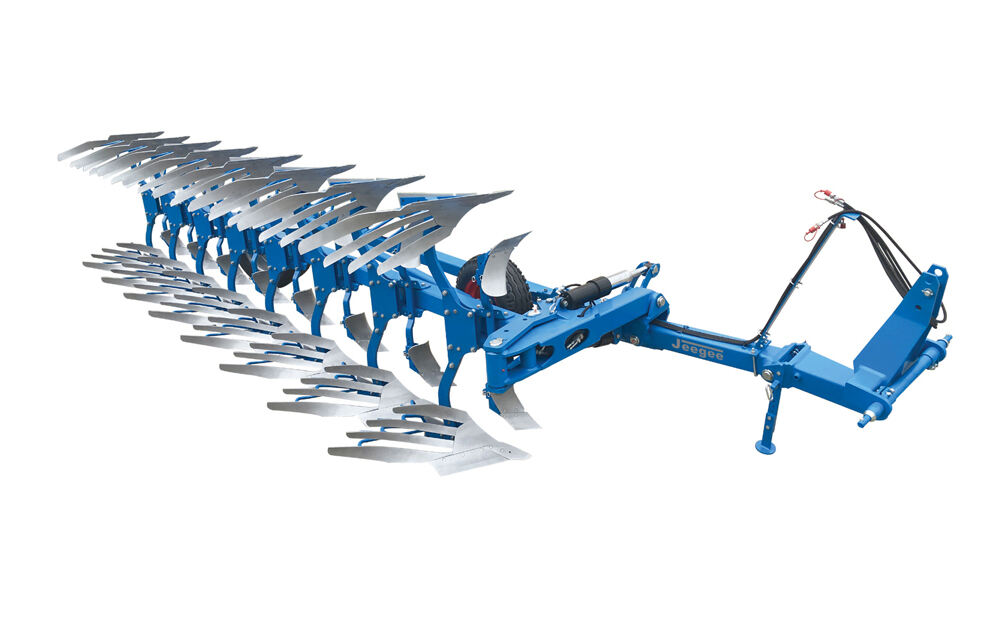

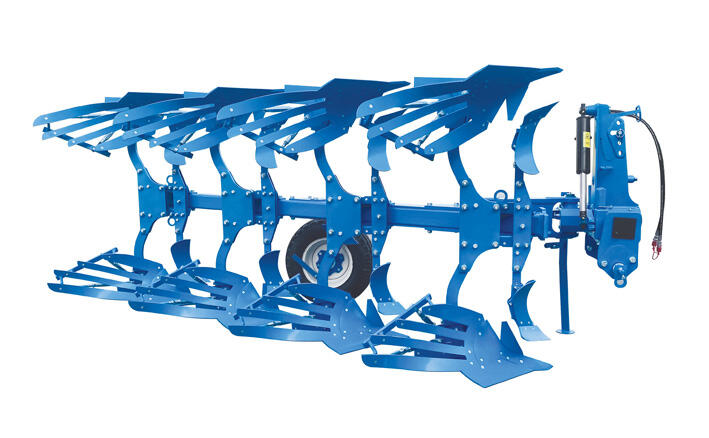

3 point disk plow

The 3 point disk plow represents a significant advancement in agricultural machinery, designed to efficiently break and turn soil while incorporating crop residue. This implement attaches to a tractor's three point hitch system, offering superior maneuverability and control during field operations. The plow typically features multiple curved steel disks mounted at specific angles to effectively cut through soil and vegetation. Each disk measures between 20 to 26 inches in diameter, rotating independently on sealed bearings to minimize maintenance requirements. The implement's robust frame construction ensures durability in challenging field conditions, while adjustable disk angles allow farmers to optimize soil penetration and turning action based on specific field conditions. The 3 point disk plow excels in primary tillage operations, particularly in heavy soil conditions or fields with significant crop residue. Its design facilitates thorough soil mixing, which helps decompose organic matter and prepare seedbeds for subsequent planting. Modern versions often include safety features such as spring-loaded disk assemblies to prevent damage when encountering obstacles, and precise depth control mechanisms to maintain consistent working depths across varying field conditions.