Mastering Disc Harrow Operations for Optimal Soil Management

The effective use of a disc harrow stands as a cornerstone of successful soil preparation and management in modern agriculture. Agricultural professionals worldwide rely on disc harrows to create ideal seedbeds, manage crop residue, and improve soil structure across diverse terrains. Understanding how to properly utilize this versatile implement across different soil conditions can significantly impact crop yields and soil health for seasons to come.

Modern farming demands precise equipment handling, and the disc harrow represents a crucial tool in the farmer's arsenal. Whether dealing with heavy clay soils or light sandy conditions, proper disc harrow operation requires a thorough understanding of soil characteristics and equipment capabilities. This comprehensive guide explores the essential practices that ensure optimal results across varying soil conditions.

Understanding Disc Harrow Components and Their Functions

Essential Parts of a Disc Harrow

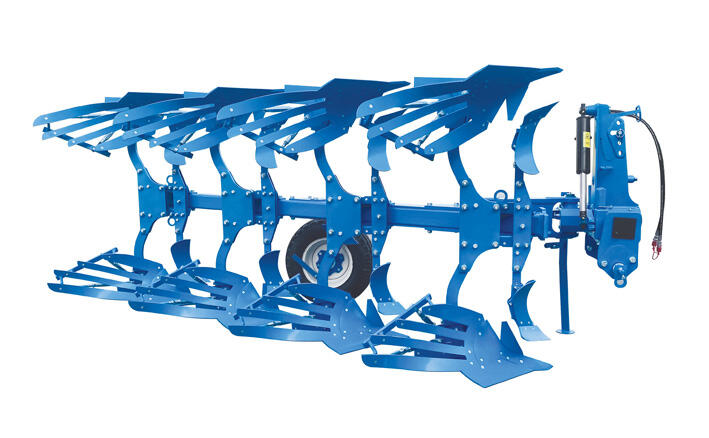

A disc harrow consists of several key components that work together to achieve effective soil cultivation. The main elements include the frame, disc blades, bearings, and gang assemblies. The disc blades, typically made from high-quality steel, come in various sizes and configurations. These blades are mounted on gangs at specific angles to optimize soil penetration and mixing.

The gang angle adjustments allow operators to control the aggressiveness of soil manipulation. Supporting components like bearings ensure smooth operation, while the frame provides the necessary structural integrity for consistent performance across different field conditions.

Configuration Options for Different Soil Types

Different soil conditions require specific disc harrow configurations to achieve optimal results. For heavy clay soils, larger diameter discs with more aggressive gang angles might be necessary. In contrast, lighter soils may benefit from smaller disc sizes and less aggressive angles to prevent over-pulverization.

Weight requirements also vary significantly based on soil conditions. Additional weight may be necessary for proper penetration in heavy soils, while lighter settings might suffice for sandier conditions. Understanding these configuration options enables operators to maximize the implement's effectiveness across varying field conditions.

Soil Assessment and Preparation Techniques

Evaluating Soil Moisture Content

Proper soil moisture assessment is crucial for successful disc harrow operation. Working soil that's too wet can lead to compaction and poor tillage results, while extremely dry conditions may cause excessive dust and inadequate soil manipulation. The ideal moisture content allows soil to crumble when compressed but not stick to equipment.

Regular monitoring of soil moisture levels helps determine the optimal timing for disc harrow operations. Experienced operators often perform simple field tests, such as the ribbon test or ball test, to evaluate soil moisture conditions before beginning work.

Timing and Weather Considerations

Weather patterns play a significant role in successful disc harrow operations. Planning work during appropriate weather windows helps achieve desired results while minimizing soil damage. Early morning or late afternoon operations often prove most effective, as moisture levels tend to be more favorable during these times.

Seasonal timing also affects disc harrow performance. Spring operations require different approaches compared to fall tillage, with soil temperature and moisture levels influencing timing decisions. Understanding these weather-related factors helps operators maximize the effectiveness of their disc harrow operations.

Operating Techniques for Maximum Efficiency

Speed and Depth Control

Operating speed significantly impacts disc harrow performance. Generally, speeds between 4-7 mph provide optimal results, though specific conditions may require adjustments. Maintaining consistent speed helps ensure uniform soil treatment and residue incorporation.

Depth control requires careful attention to achieve desired results. Too shallow operation may leave residue poorly incorporated, while excessive depth can create unwanted soil structure issues. Regular monitoring and adjustment of working depth helps maintain optimal performance across varying field conditions.

Pattern and Overlap Considerations

Proper operating patterns enhance disc harrow efficiency and effectiveness. Cross-disking often provides better residue incorporation and soil mixing compared to single-direction passes. Maintaining appropriate overlap between passes ensures complete coverage and uniform soil treatment.

Field conditions and specific goals influence pattern selection. Contour operation on slopes helps prevent erosion, while straight patterns may prove more efficient on level ground. Adapting patterns to field conditions optimizes both efficiency and results.

Maintenance and Performance Optimization

Regular Equipment Inspection

Systematic maintenance ensures reliable disc harrow performance. Regular inspection of disc blade condition, bearing health, and frame integrity helps prevent unexpected breakdowns. Worn components should be replaced promptly to maintain optimal performance.

Checking and maintaining proper gang angles and spacing ensures consistent soil treatment. Lubrication schedules must be followed diligently, particularly when operating in challenging conditions that may accelerate wear.

Adjustment and Calibration Procedures

Proper adjustment and calibration procedures maintain disc harrow effectiveness. Regular checking of gang angles, disc spacing, and leveling helps ensure optimal performance. These adjustments often require modification based on changing soil conditions or operational goals.

Documentation of optimal settings for different field conditions helps streamline future operations. Creating and maintaining adjustment records enables quick setup changes when moving between different soil types or field conditions.

Frequently Asked Questions

How often should disc harrow blades be replaced?

Disc harrow blades typically require replacement when their diameter has been reduced by 4-5 inches from original size, or when they show significant wear patterns that affect performance. Regular measurement and inspection help determine optimal replacement timing.

What is the ideal moisture content for disc harrowing?

The ideal soil moisture content for disc harrowing is typically between 40-60% of field capacity. At this range, soil crumbles easily without being too wet or too dry, allowing for optimal tillage results and minimal compaction risk.

How can I prevent soil compaction during disc harrow operations?

To prevent soil compaction, avoid operating when soil is too wet, maintain appropriate speed and depth settings, and consider using flotation tires or tracks on pulling equipment. Implementing controlled traffic patterns and monitoring soil moisture conditions also helps minimize compaction risks.