Understanding Soil Types and Plough Requirements

Clay Soil: Weight Distribution and Plough Penetration

Working with clay soil can be quite challenging because of how tightly packed it tends to be when it comes to getting a plough through. Farmers need to pay attention to how weight is spread across their equipment if they want good results. When the plough has proper balance, the blades will slice through the compacted earth much more consistently. Moisture levels matter too. Clay gets really tricky when wet, so adjusting both the weight on the plough and how fast it moves makes all the difference. Most experienced growers know that going slower and adding extra ballast helps break up soggy clay without damaging the ground. Studies have shown curved blades work best for these conditions, turning over the soil better which lets air circulate and prevents the ground from becoming too hard packed after repeated passes.

Sandy Soil: Speed Control and Furrow Stability

Working with sandy soil is tricky because of how loose it gets. Farmers need to watch their speed when ploughing these areas if they want those furrows to hold together properly. Going too fast just kicks up all that sand and messes everything up. Most folks find that keeping things around 4 to 6 mph works pretty well for getting through sandy ground without causing problems. The angle of the plough matters too. Experts say adjusting it right helps cut down on erosion, which is always a concern in these types of soils. For reversible ploughs, farmers often add extra support wheels or stabilizers. These little modifications make a big difference in keeping the furrows straight even when the land isn't perfectly flat.

Loamy Soil: Balancing Depth and Moisture Retention

Farmers know loamy soil works best for growing stuff because it mixes sand, silt, and clay just right. But getting the plowing depth right matters a lot when it comes to keeping moisture where plants need it. Most agronomy books will tell folks to go between six and eight inches deep for regular crops, though specifics change based on what's actually being planted. Corn might need something different than wheat or soybeans. The magic happens at this depth range since roots can spread out properly while still holding onto enough water. Reversible plows really shine in loamy soils across different farms. These tools turn over the earth just enough without messing things up too much, which means better harvests overall. A local farmer once told me how switching to reversible plows made all the difference for his potato patch last season.

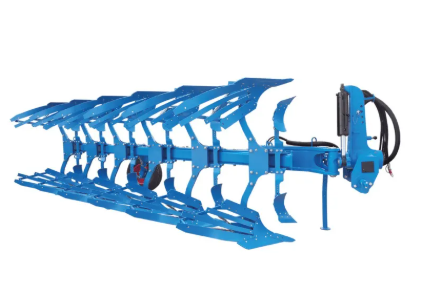

Key Features of Reversible Ploughs for Specific Conditions

Hydraulic Systems for Precision Adjustments

The hydraulics in reversible plows really matter because they let farmers tweak things just right when dealing with different kinds of dirt across fields. These systems come with some pretty good specs that actually make a difference in how responsive the plow feels while working through tough spots or softer ground. Better hydraulics mean farmers can control how deep the plow goes into the earth, which keeps everything consistent without having to constantly jump out of the tractor to fix things manually. Most experienced growers will tell anyone who asks that upgrading to smarter hydraulic setups makes all the difference in getting those straight lines and even furrows across their land.

Mouldboard Design Variations for Soil Turnover

How a mouldboard is shaped makes all the difference when it comes to turning over soil effectively across various ground conditions. Farmers who invest in properly engineered mouldboards find they can dig deeper into compacted earth while also creating better air pockets in the soil profile, something that really helps plants grow healthier roots. Some newer models feature sharper curves along the cutting edge and stronger steel alloys that hold up longer against tough field work. These improvements mean dirt gets flipped over just right so nutrients stay where crops need them most. Field tests from several farming regions indicate that switching to these advanced designs often results in better harvests and soils that hold water more efficiently after rainfalls, which explains why many progressive growers consider mouldboard selection essential for their bottom line.

Coulter and Disc Configurations for Tough Terrain

The way coulters and discs are set up on ploughs makes all the difference when dealing with tough ground or rocky patches, something farmers face regularly across many farming areas from the Midwest to parts of Australia. Farmers have noticed that certain setups cut through soil better while putting less strain on the machine itself, meaning the plough lasts longer between repairs. Field tests and farmer reports consistently show some configurations work much better than others, especially in clay soils or areas with hidden stones. Getting these settings right isn't just about making the job easier it actually saves money over time and helps keep the land healthy for future crops too.

Incorporating these key features into reversible ploughs will ensure adaptability and efficiency in diverse soil conditions, aiding significantly in optimizing soil health and agricultural productivity.

Matching Plough Specifications to Farm Needs

Tractor Horsepower and Implement Compatibility

Getting the right balance between tractor horsepower and reversible plough specs makes all the difference when it comes to getting good results in the fields and keeping the soil healthy. The amount of power a tractor has basically decides what size plough will work best together, which affects how efficiently work gets done across different types of land. When trying to pair up these specs, most folks rely on what the manufacturers recommend regarding power ranges for various plough sizes depending on what kind of ground they're working with. Farmers who ignore this matching process often end up with problems down the road. If the tractor doesn't have enough power behind it, the plough just won't cut through properly, leaving the soil poorly cultivated while putting extra strain on both equipment and operator alike. Soil quality suffers too because inadequate force means incomplete tilling action throughout the field.

Furrow Width and Depth Requirements by Crop Type

Getting the right furrow width and depth matters a lot when it comes to maximizing what we get out of our fields because different plants need different conditions in the dirt below them. Farmers who take time to figure out exactly what their particular crops require tend to see much better results in terms of both how well the plants grow and their final quality. Many growers find it really helpful to check out charts comparing recommended furrow sizes against various root structures and plant life cycles. Studies in farming science back this up too showing that following these guidelines helps roots grab onto nutrients much better, leading to healthier harvests across the board. When furrows are set correctly, air gets into the soil properly and water stays where it needs to be without running off or sitting around too long, something absolutely vital if we want strong healthy crops developing throughout the season.

Field Size and Terrain Considerations

When choosing a reversible plough, farmers need to think about field size and terrain because these factors really affect how well the equipment works in the field. Big open fields often call for heavy duty ploughs that can handle large areas without breaking down, whereas small plots need something that turns easily around corners and fits through gates. The ground itself matters too. Fields with hills or lots of rocks will wear out regular ploughs faster, so special models designed for rough spots tend to last longer and work better. Talking to other farmers who've faced similar challenges helps a lot. Some folks swear by particular plough setups for hilly land, which makes sense since those configurations actually cut through tough terrain without tearing up the soil as much as standard models do.

For more insights on choosing the perfect reversible plough for your soil type, the Mounted Reversible Plough L7 and L8 models offer advanced hydraulic systems and adaptable frame sizes to match various tractor specifications efficiently, ensuring optimal farming results.

Setup Techniques for Optimal Soil Preparation

Calibrating Depth Settings for Soil Moisture Levels

Getting the plough depth right according to soil moisture makes all the difference when it comes to preserving soil structure. When calibrated properly, the plough works with the soil rather than against it, keeping moisture where it belongs and making sure the work gets done efficiently. Farmers who've studied this stuff know that setting the plough just right cuts down on moisture escaping from the ground, which ultimately leads to healthier soils over time. But many run into trouble because they set their plough too deep or too shallow. This creates problems with how the soil turns over and wastes fuel while doing less effective work. The best approach? Stick closely to what the equipment maker recommends and check those soil moisture readings frequently throughout the season. Small tweaks here and there based on actual conditions will make a big impact in the long run.

Adjusting Coulter Angle for Consistent Trash Burial

Getting the coulter angle right makes all the difference when it comes to burying trash properly, cutting down on residue buildup, and actually improving what's going on in the soil. When farmers set those angles correctly, they get better residue coverage across their fields, something that matters a lot for planting later on. Want to know how to tweak this? Start by looking at how much trash there really is in the field first. Then adjust the angle so everything gets buried completely underneath. Don't forget to check back regularly after making these changes to see if the soil quality improves over time. Farmers who take care with their coulter angles often notice healthier soils and better results come springtime.

Balancing Plough Weight for Even Soil Turnover

Getting good soil turnover starts with getting the weight right on those plows. When the weight is spread out evenly across the implement, it makes a big difference in how the soil gets turned over, which affects everything from soil structure to what crops grow where. Farmers who've dealt with uneven plow weights know firsthand what happens when things aren't balanced - patches of compacted ground here and there, lower yields across the board. Research backs this up too, showing fields with unbalanced plows often struggle with inconsistent planting beds. Adjusting plow weight isn't complicated but requires some field observation first. Check moisture levels, look at previous crop residues, then start adding or taking away ballast until the plow feels right in operation. Soil conditions change throughout the season, so regular checks and adjustments keep things working smoothly. Smart farmers understand that maintaining proper weight distribution isn't just about equipment maintenance, it's about protecting long term soil fertility.

Maintenance Practices to Enhance Plough Efficiency

Sharpening Blades for Reduced Fuel Consumption

Keeping those plough blades sharp makes all the difference when it comes to getting through fields efficiently without burning through extra fuel. Dull blades create drag that forces tractors to work harder, which means higher fuel bills at the end of the day. Some field tests back this up showing farmers can save around 15% on fuel costs just by maintaining sharp blades. For most operations, a good rule of thumb is to sharpen blades after about 20 to 30 hours of actual ploughing time. Don't forget to clean off any rust spots or dirt buildup while doing so. Many experienced farmers keep an extra set of blades handy somewhere nearby. Makes life so much easier when something breaks down mid-field and there's no waiting around for replacement parts to arrive.

Lubricating Hydraulic Components in Harsh Conditions

Getting the right amount of lubricant into those hydraulic bits makes all the difference when it comes to how long plough systems last and how well they work, particularly out there on farms where things get tough. When everything's properly oiled up, those moving parts glide along without grinding against each other, which means less damage over time and keeps them working backward as needed too. Farmers who skip regular greasing often end up paying through the nose for repairs later on, not to mention their equipment just plain works worse. A good idea is to set up some sort of maintenance routine based on what kind of weather or soil conditions are typical around the farm. Maybe check once a week if it's mostly dry ground, but bump that up to daily when dealing with mud or dust storms. This kind of proactive approach really pays off in the long run for keeping those expensive hydraulic systems running smoothly season after season.

Inspecting Wear Parts: Shares, Shins, and Landslides

Checking wear parts such as shares, shins, and landslides regularly is really important if farmers want their ploughs to keep performing well over time. These bits take a real beating during operation because they're constantly grinding against tough ground conditions, and when they start showing signs of wear, it affects how the soil gets worked and ultimately impacts harvest quality. Farmers who pay attention to how these parts wear down tend to spot problems before they become major issues. Take replacement timing for example – getting new parts installed while there's still some life left in the old ones can cut maintenance expenses by around 25% versus waiting until complete failure occurs. Most experienced operators establish monthly check routines and maintain records tracking each component's condition. This approach helps them plan replacements at convenient times rather than dealing with unexpected breakdowns during critical planting seasons.

FAQs

What types of soil are discussed in this article?

The article discusses clay, sandy, and loamy soil types each requiring specific ploughing techniques.

How does tractor horsepower affect plough performance?

Tractor horsepower is crucial in determining the compatibility with plough specifications, impacting efficiency during field operations.

What are the recommended furrow specifications based on soil type?

The recommended ploughing depth for loamy soil is 6 to 8 inches, while sandy soil requires controlled speed for furrow stability.

How can hydraulic systems improve plough precision?

Hydraulic systems allow for precise adjustments in plough settings, enhancing responsiveness and efficiency in various soil conditions.