Understanding Agricultural Plough Selection for Optimal Soil Management

Selecting the appropriate types of plough for your agricultural needs is a crucial decision that can significantly impact crop yield and soil health. Modern farming demands careful consideration of various factors when choosing ploughing equipment, as different soil conditions require specific approaches to cultivation. This comprehensive guide will help you navigate the complex world of agricultural ploughs and make an informed decision for your farming operations.

Essential Types of Plough and Their Applications

Moldboard Plough Characteristics

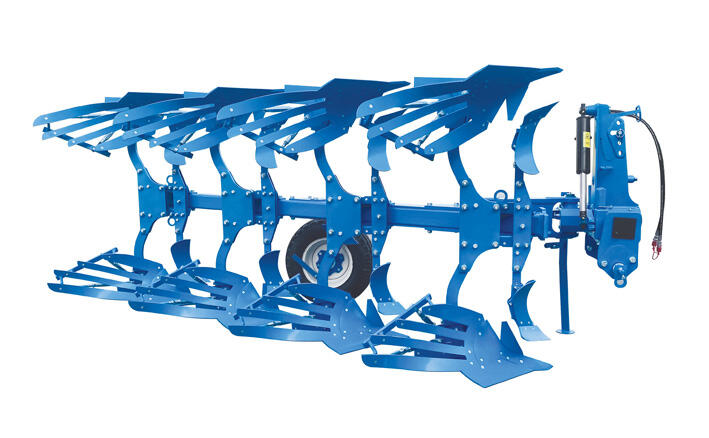

The moldboard plough remains one of the most widely used types of plough in traditional farming. Its primary function involves turning over and inverting the soil completely, which helps bury crop residue, weeds, and surface vegetation. This plough type works exceptionally well in medium to heavy soils, creating a clean furrow while maintaining proper soil structure. The curved moldboard design facilitates smooth soil flow and proper incorporation of organic matter.

Disc Plough Benefits

Disc ploughs excel in challenging soil conditions where conventional moldboard ploughs might struggle. These types of plough feature rotating disc blades that cut and turn the soil effectively. They perform particularly well in sticky, rocky, or hard soil conditions, making them ideal for regions with varying soil compositions. The rolling action of disc ploughs requires less draft power compared to moldboard ploughs, resulting in improved fuel efficiency.

Chisel Plough Applications

For conservation tillage practices, chisel ploughs offer an excellent solution. These types of plough work by breaking up soil compaction while leaving crop residue on the surface, which helps prevent erosion. They're particularly effective in dry farming conditions and areas prone to wind erosion. The reduced soil disturbance promotes better moisture retention and soil structure preservation.

Soil Condition Assessment and Plough Selection

Analyzing Soil Texture and Structure

Before selecting a plough, conducting a thorough soil analysis is essential. Sandy soils typically require different types of plough compared to clay-heavy soils. Light soils benefit from implements that can maintain moisture and prevent excessive loosening, while heavy soils need ploughs that can effectively break up compacted layers without creating hardpan conditions.

Moisture Content Considerations

Soil moisture levels play a crucial role in plough selection and operation. Working with wet soil can lead to compaction and structure damage, while extremely dry conditions may require more powerful equipment. Understanding your region's seasonal moisture patterns helps determine the most suitable types of plough for your specific situation.

Technical Specifications and Performance Factors

Working Depth Requirements

Different crops and farming practices require varying ploughing depths. Modern types of plough come with adjustable depth settings to accommodate these needs. Shallow ploughing might be sufficient for certain crops, while others benefit from deeper soil manipulation. The ability to adjust working depth allows farmers to optimize their ploughing operations based on specific crop requirements and soil conditions.

Power Requirements and Efficiency

Tractor power matching is crucial when selecting a plough. Different types of plough have varying power requirements, which must align with your available tractor capacity. Consider factors such as fuel efficiency, working width, and operation speed when evaluating plough options. Proper power matching ensures optimal performance and prevents unnecessary strain on equipment.

Economic and Environmental Considerations

Cost Analysis and Return on Investment

Investing in the right types of plough requires careful financial planning. Consider both initial purchase costs and long-term operational expenses, including maintenance, fuel consumption, and potential repair needs. While premium ploughs may have higher upfront costs, their durability and efficiency often provide better long-term value.

Environmental Impact Assessment

Modern farming increasingly emphasizes environmental sustainability. Different types of plough vary in their environmental impact, particularly regarding soil erosion, organic matter preservation, and carbon footprint. Conservation ploughs that maintain surface residue while achieving desired tillage results often represent the best balance between productivity and environmental stewardship.

Maintenance and Optimization

Regular Maintenance Protocols

Proper maintenance extends equipment life and ensures consistent performance. Different types of plough require specific maintenance routines, including regular inspection of wearing parts, proper lubrication, and timely replacement of components. Establishing a systematic maintenance schedule helps prevent unexpected breakdowns and maintains optimal ploughing efficiency.

Performance Optimization Strategies

Fine-tuning plough settings for specific conditions maximizes efficiency and results. This includes adjusting working angles, depth settings, and forward speeds according to soil conditions and desired outcomes. Regular monitoring and adjustment of these parameters ensure consistent ploughing quality across different field conditions.

Frequently Asked Questions

What factors should I consider when choosing between different types of plough?

Consider your soil type, typical moisture conditions, crop requirements, available tractor power, and local climate patterns. Also evaluate the presence of rocks or other obstacles, desired working depth, and your specific conservation goals.

How often should agricultural ploughs be replaced?

The lifespan of a plough depends on usage intensity, maintenance quality, and operating conditions. With proper maintenance, most types of plough can last 8-12 years, though wearing parts require regular replacement based on use.

Can I use the same plough type for all seasons?

While some types of plough are more versatile than others, seasonal variations in soil conditions might require different implements for optimal results. Many farmers maintain multiple plough types or use combination implements to address varying seasonal needs effectively.

Table of Contents

- Understanding Agricultural Plough Selection for Optimal Soil Management

- Essential Types of Plough and Their Applications

- Soil Condition Assessment and Plough Selection

- Technical Specifications and Performance Factors

- Economic and Environmental Considerations

- Maintenance and Optimization

- Frequently Asked Questions