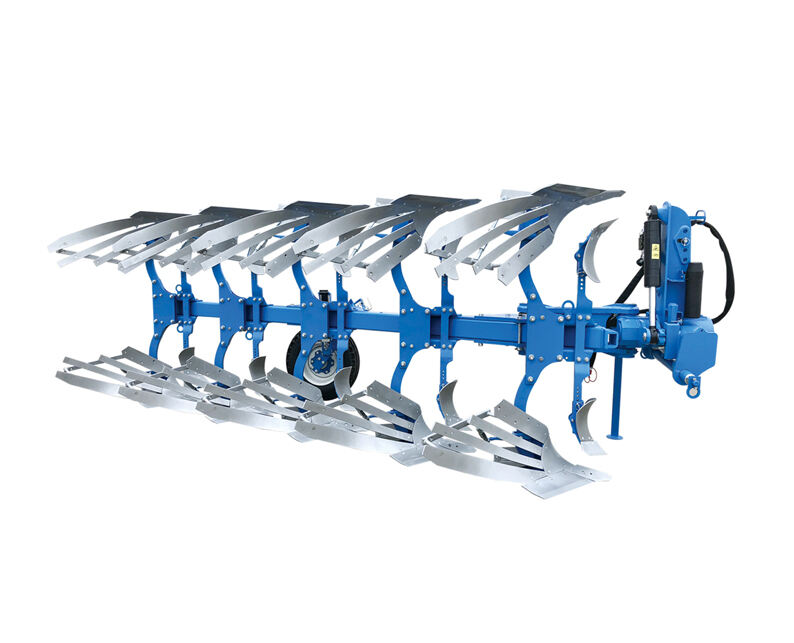

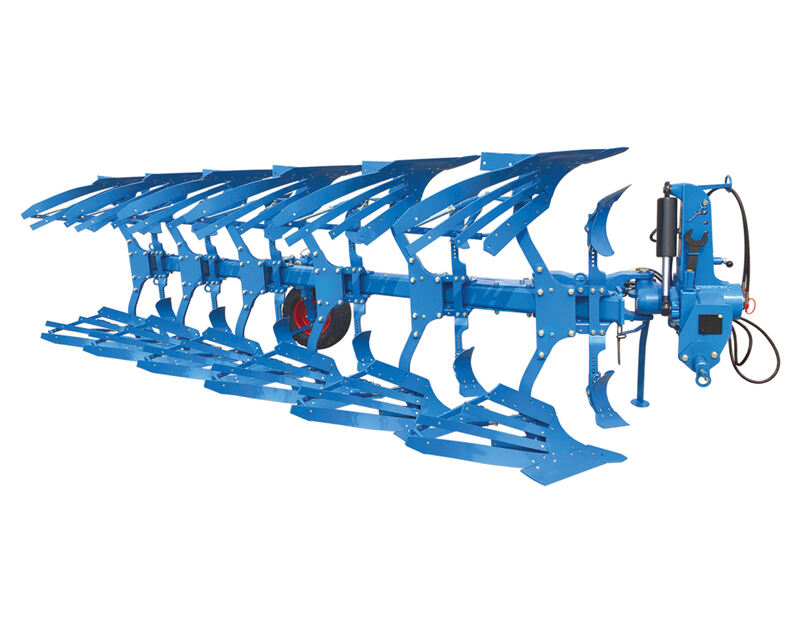

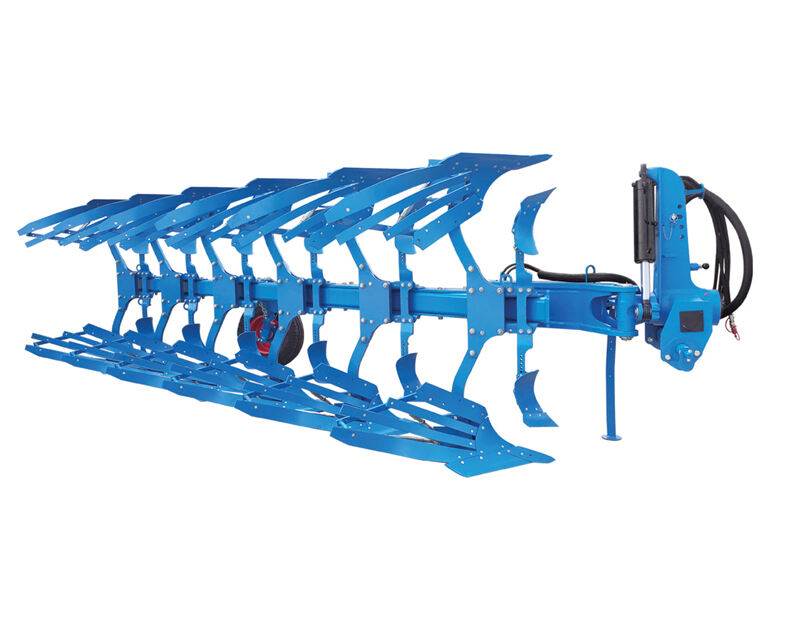

reaper machine for agriculture

The reaper machine represents a revolutionary advancement in agricultural technology, designed to efficiently harvest crops with precision and speed. This mechanical harvester consists of a cutting mechanism, a reel to gather crops, and a platform for collecting cut stems. The machine operates through a combination of rotating blades and gathering mechanisms that work in tandem to cut crops at a consistent height. Modern reapers incorporate advanced features such as adjustable cutting heights, automated controls, and enhanced safety mechanisms. The cutting bar, typically ranging from 4 to 12 feet in width, allows for efficient harvesting of various crop types, including wheat, rice, and other cereal grains. The machine's design includes a series of reciprocating knife sections that move against stationary guard fingers, creating a clean and precise cut. Technological innovations have led to the integration of GPS guidance systems, yield monitors, and computerized controls that optimize harvesting operations. The reaper's mobility is enhanced through either self-propelled systems or tractor-drawn implementations, providing flexibility for different farm sizes and terrains. This versatile machine has transformed agricultural practices by reducing manual labor requirements and significantly increasing harvesting efficiency, making it an indispensable tool in modern farming operations.