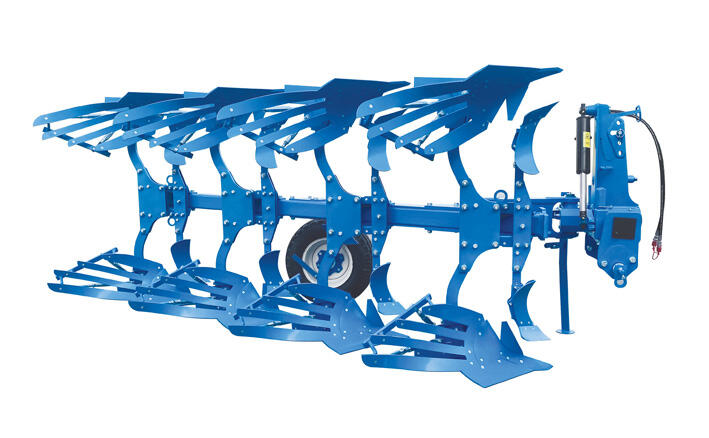

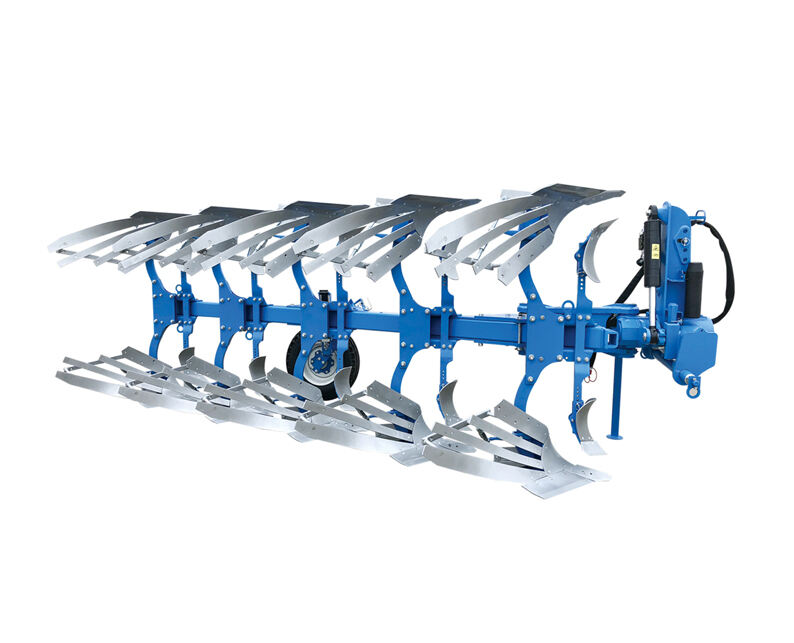

harrow disc plough

The harrow disc plough is an advanced agricultural implement that combines the functions of both ploughing and harrowing in a single efficient operation. This versatile piece of equipment features a series of concave discs mounted at specific angles on a robust frame, designed to effectively cut, lift, and turn over soil while simultaneously breaking down clods and leveling the surface. The implement typically consists of multiple disc gangs that can be adjusted for various working depths and angles, making it suitable for different soil conditions and cultivation requirements. The discs, usually made from high-grade steel with heat-treated edges, rotate freely as they move through the soil, reducing the power requirement compared to conventional moldboard ploughs. One of the most significant technological features is the independent disc suspension system, which allows each disc to navigate obstacles independently, maintaining consistent working depth across uneven terrain. The harrow disc plough excels in handling crop residue, incorporating organic matter into the soil while preparing an ideal seedbed. It's particularly effective in heavy soils, virgin land, and areas with significant plant residue, making it an invaluable tool for both primary and secondary tillage operations.