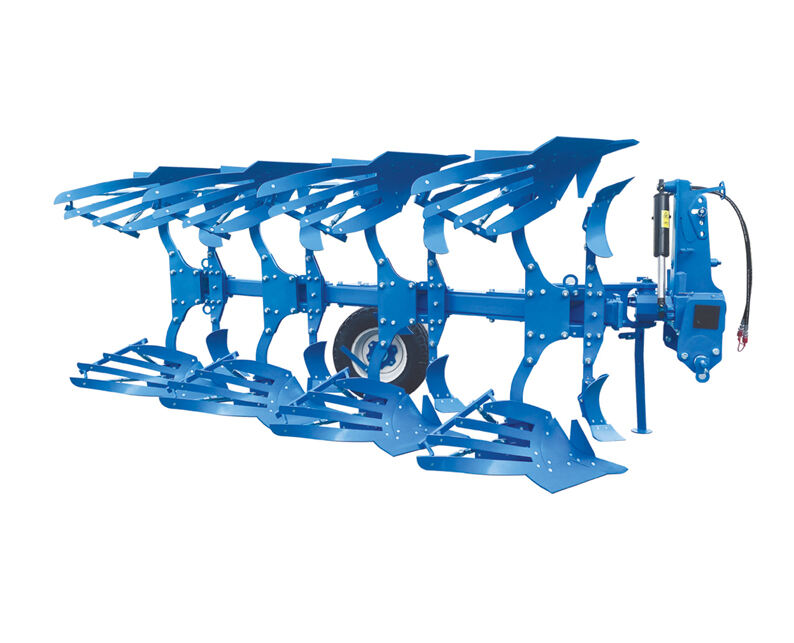

double action disc harrow

The double action disc harrow represents a significant advancement in agricultural machinery, designed to efficiently prepare soil for planting through a comprehensive dual-action mechanism. This implement features two sets of offset disc gangs that work in tandem to thoroughly mix and break down soil clumps while managing crop residue. The front gangs typically throw soil outward, while the rear gangs return it inward, creating a well-balanced and uniformly tilled seedbed. Built with precision-engineered disc blades ranging from 20 to 24 inches in diameter, these harrows can penetrate soil depths of 4 to 8 inches, depending on operating conditions and adjustments. The machine's robust frame construction supports heavy-duty bearings and axles, ensuring reliable performance in challenging field conditions. Modern double action disc harrows often incorporate hydraulic systems for precise depth control and transport convenience, along with adjustable gang angles that allow operators to fine-tune soil manipulation intensity. This versatility makes them particularly valuable for both primary and secondary tillage operations, especially in situations requiring thorough residue incorporation and soil structure improvement.