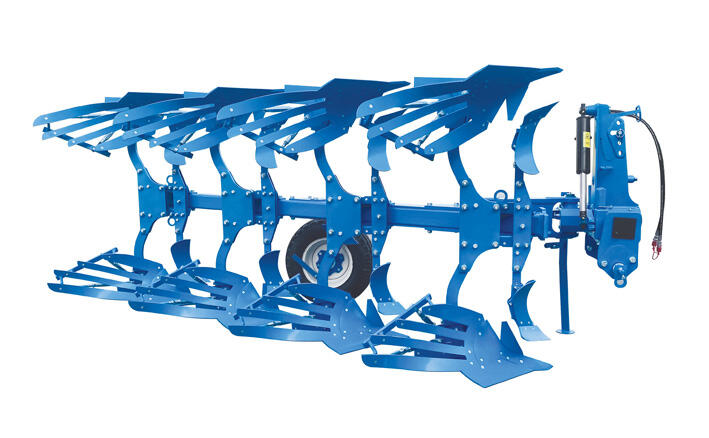

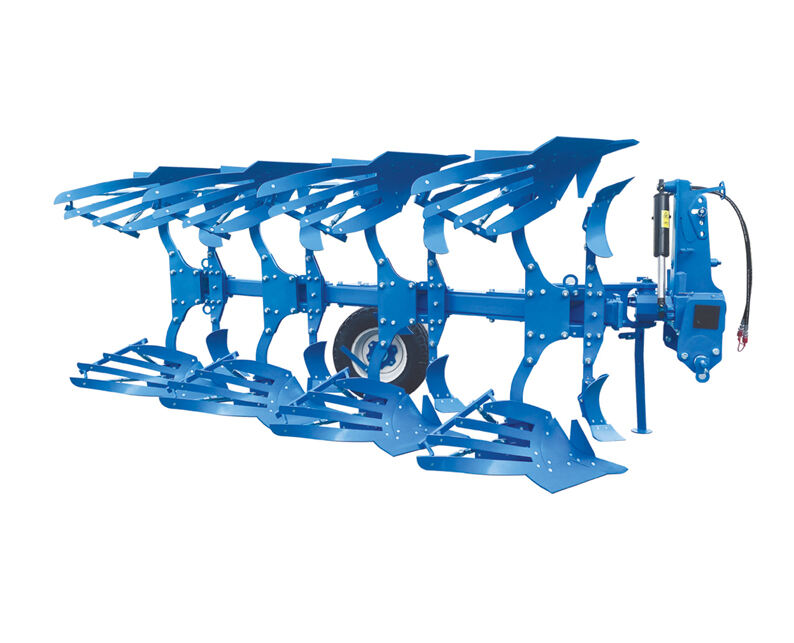

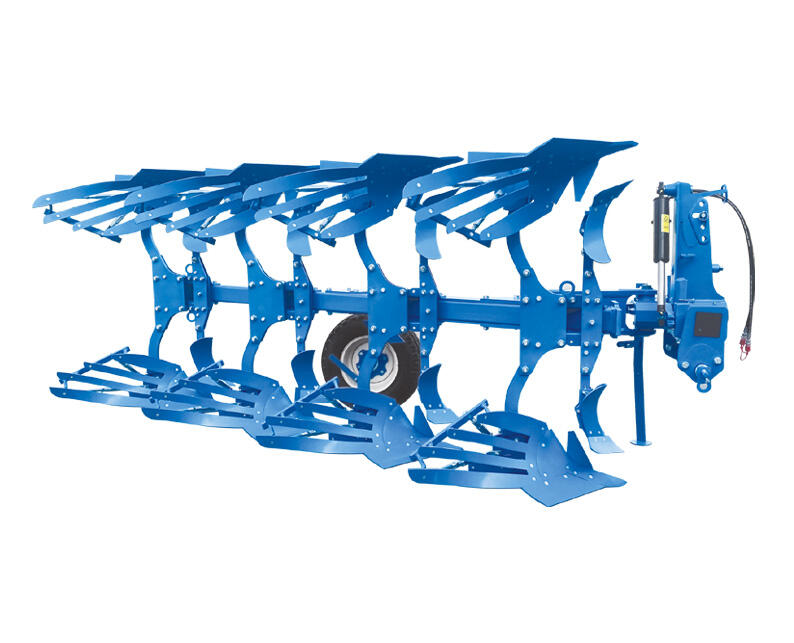

agriculture reaper machine

The agriculture reaper machine represents a significant advancement in modern farming technology, designed to efficiently harvest crops while minimizing labor requirements. This versatile implement operates by cutting and gathering crops in a single pass, significantly reducing harvest time and operational costs. The machine features a cutting mechanism consisting of sharp blades mounted on a horizontal bar, which moves back and forth against stationary fingers to create a scissor-like cutting action. The standard reaper includes essential components such as the cutting platform, reel, conveyor system, and power transmission mechanism. Advanced models incorporate automated height adjustment systems, precision cutting controls, and ergonomic operator interfaces. The machine can effectively handle various crop types, including wheat, rice, barley, and other small grains, with cutting widths typically ranging from 4 to 8 feet. Modern reapers often include features such as adjustable cutting heights, variable speed controls, and crop dividers to ensure clean, efficient harvesting. The technology employs either self-propelled or tractor-mounted configurations, allowing farmers to choose the most suitable option for their specific needs. These machines are designed with durability in mind, constructed from high-grade materials to withstand intensive use and varying field conditions.